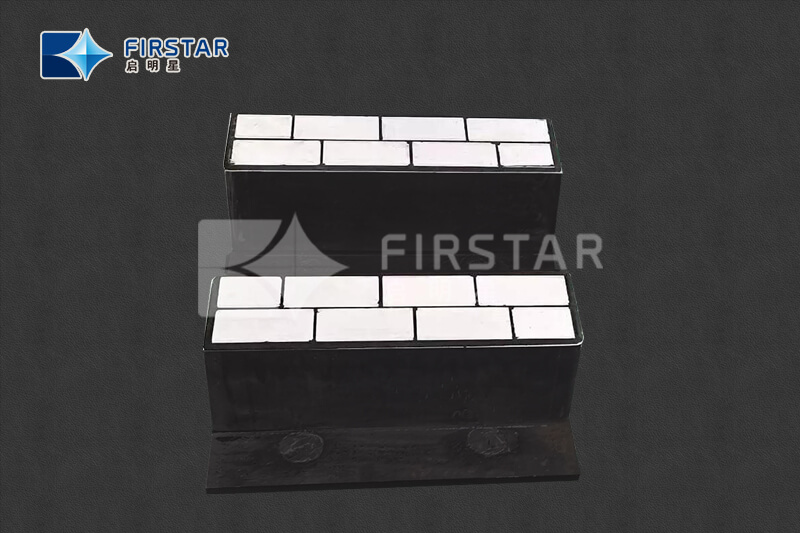

Engineering alumina ceramic liner is different standard ceramic tile , designed and tailor-made with CAD Software to suit any type of customer’s components . QMX ceramics offer a range of wear resistant ceramics products that have been engineered to meet the equipment abrasive requirement of special angle , shape,radian,sizes etc.which can be perfectly installed without gaps and fitted for equipment. QMX has experienced to design engineering alumina tiler chute liner like hopper liner , cyclone liner etc. Also will help with your wear problems well .

Products Characters :

-- Long lifetime and maintenance free operation

-- No operation interruption or production losses

-- Maximum efficiency of separation

--Perfectly fit for equipment without cutting

Application industry

> mining industry

> Cement industry

> Coal handling industry

> Steel industry

> Port industry

> Power plant

Technical data :Chemical Composition:

Al2O3 | SiO2 | CaO | MgO | Na2O |

92~93% | 3~6% | 1~1.6% | 0.2~0.8% | 0.1% |

Physical Properties:

| Specific gravity (g/cc) | >3.60 | >3.65 | >3.70 |

| Apparent porosity (%) | 0 | 0 | 0 |

| Bending Strength (20℃, Mpa) | 220 | 250 | 300 |

| Compressive strength (20℃, Mpa) | 1050 | 1300 | 1600 |

| Rockwell hardness (HRA) | 82 | 85 | 88 |

| Vickers hardness (HV20) | 1050 | 1150 | 1200 |

| Moh’s hardness (scale) | ≥9 | ≥9 | ≥9 |

| Thermal Expansion (20-800℃, x10-6/℃) | 8 | 8 | 8 |

| Abrasion Loss (Cm3) | 0.25 | 0.2 | 0.15 |