and Wear Resistant Products

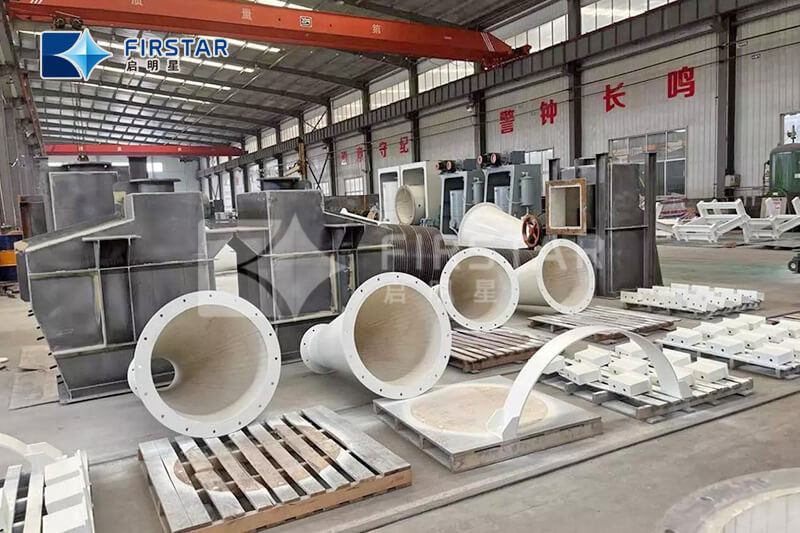

Mining Wear Ceramic Lined Part and ComponentsQMX can supply hydro cyclone replacement liners for OEM cyclones. Liners are generally composed of:Silicon CarbideAlumina orcomposite ceramic Liner In situations where ceramic materials may not be suitable, we also supply linings made from:Polyurethane orRubberPipe LiningsOur ceramic pipe linings have been used in very abrasive environments.They are produced from high purity (92% or 99.8%), high density Alumina.They exhibit around 8 - 10 times the wear life of comparative materials, ie steels, rubbers and polyurethanes.We stock various straight and elbow sections and can tailor to your needs.Wear Resistant Ceramic Lined Vortex Finder Wear Resistant 45°Pipe Bend Wear Resistant Cyclone Distributor

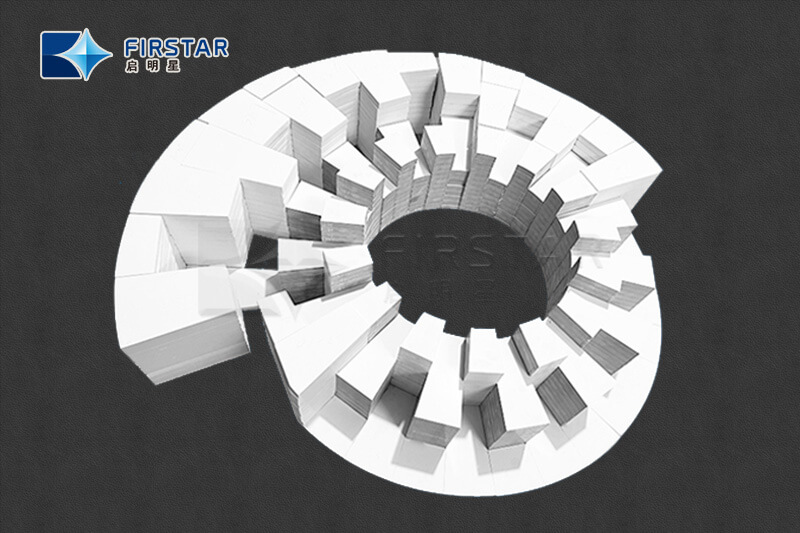

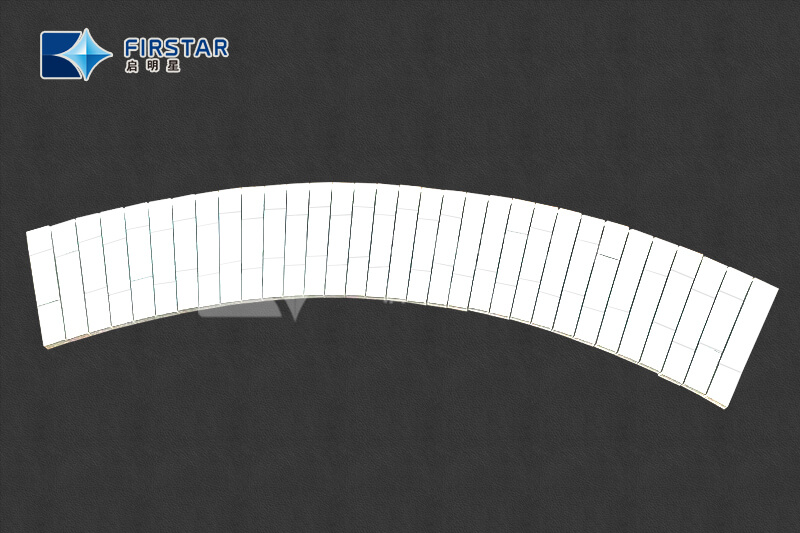

A cyclone is a specially designed system used to separate materials using centrifugal forces. The materials fed into a cyclone are typically hard and the environment within a cyclone is inherently highly abrasive. Hence wear inside a cyclone is an operational hazard. QMX Ceramic Engineering have the materials and expertise to be able to minimize wear of your cyclone linings and thus reduce downtime and increase efficiency.The main body of the cyclone consists of a reducer or a cone shaped liner tapering from a larger diameter to a smaller one down its length.Wear Resistant Solutions for CyclonesSince the materials separated in a cyclone are highly abrasive, it is important to have a cyclone lining that stands up to rigors of the job. Ultra High Purity Alumina can be used to increase cyclone working life and performance and can be custom shaped to suit all geometries; from the pipe work leading to the inlet, the vortex finder and apex outlet, to the conical heart of the cyclone.Cyclone Components Commonly Subject to WearThere are many components within a cyclone assembly that are subject to high wear conditions. Taylor Ceramic Engineering can supply many of these in wear resistant materials to extend component life. Some of the parts that we typically supply include:· Cylindrical & Reducing Liners· Inlets· Outlets· Spigots· Inserts· Upper, Mid & Lower Cone Sections· Vortex finders· Virtually any surface that undergoes wear!Wear Resistant Lining FormatsA range of wear resistant lining techniques can be used; from monolithic inserts to tiled sections.Monolithic SectionsQMX is uniquely positioned to be able to manufacture small and large monolithic shapes in short time frames. These sections can be custom made to suit your precise requirements.Monolithic sections have the advantage that they are much faster to install, thus reducing downtime.Tiled SectionsBecause most surfaces associated with a cyclone assembly are curved, Taylor Ceramic Engineering is able to engineer tiles that conform to the exact shape required.Flat tiles on curved surfaces often leave a series of flats radially around the internal surface of the cyclone. This not only interrupts material flow but increases wear on the tiled surfaces and thus reduces equipment life. However, using engineered curved tiles that conform to the required shape reduces the discontinuities and increases material flows and hence the equipment efficiency.CategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95% ≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density≥3.50g/ cm3≥3.60g/cm3≥3.65g/cm3≥3.70g/cm3≥3.83g/cm3≥4.10g/cm3≥5.90g/cm3Water Absorption≤0.1%≤0.1%≤0.1%≤0.1%≤0.1%≤0.1%≤0.1%HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3Layout of Drawing:

Material of Cyclone liner 1. Alumina2. RBSiC silicon carbide3. ZTA Dimensions can be customized by client’s request. Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment. Product Introduction: Seperator cyclone equipment is mainly abrasive damaged by handling material, QMX can design ceramic cyclone liners according to customer's cyclone size and wear resistance requirement. ceramic tile liner cut and then composed . Product Application: Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment. We have our technical team who can help the client to choose the suitable wear resistant ceramic products ,and also we have the ability to design and make the CAD drawings according to the client’s wear application. The Tailor-made ceramics had the advantage of low wear, high hardness and impact resistance , it widely used for the chutes, hoppers, bunkers , pipelines in the mining, power generation, steel plant, steel plant industries, it make cost effective performance and reduce the maintenance cost and down-time for the clients

RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardness with high strength,high wear resistance, corrosion resistance, high temperature resistance, which has been widely used as the liners or parts in corase particles classification, concentration, paper making, chemical, electronics, washing and mineral processing industry. Property:*Superior wear resistance, impact resistance and corrosion resistance*Excellent flatness and temperature resistance up to 1380℃*Excellent oxidation resistance* Good dimensional control of complex shapes*Easy installation* Longer service life ( about 5 times more than that of alumina ceramic and 6 times more than that of polyurethane) Applicaion of RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardness :RBSiC ( SiSiC ) silicon carbide sic cyclone parts / cyclone lining with high hardness has high hardness, high temperature, abrasion resistance, oxidation resistance, acid and alkali resistance characteristics,which is widely used for wear-resisting lining of hydraulic cyclones, flue gas desulphurization pipes and coal slurry conveyor pipelines.Thickness available: 4mm - 25mmShape available: Tubes , Tee pipes, Elbows, Cones, Rings and so on. Other RBSiC / SiSiC reaction bonded silicon carbide products:The main products of reaction bonded silicon carbide ceramics are: cross beams, rollers, coling air pipe,burner nozzles,thermocouple protecting tubes,temperature measuring parts, radiant tubes, desulfurization nozzles, crucible,batts, wear resistant lining materials,plates, seals, rings and special shaped structural parts.

Cyclone mainly handles different sizes of dust particle.and suffer heavy wear damage during long time operation .which inevitably cause cyclone equipment ,even whole equipment working link stop to work and kinds of maintenance cost . Engineered Alumina ceramic lining tile design lined cyclone maximum efficiency of separation. QMX can design wear ceramic liner for any size cyclone , no matter wet or dry application.

Ceramic Lined Cyclone parts provides exceptional wear resistant property and are used highly wear prone areas like apex, cone, vertex finder etc area. In the industries like coal production, power generation, mineral processing and many other application entire cyclones are lined with ceramic liner.Features of our Ceramic Lined Cyclones:· The ultimate in alumina tiled cyclone engineering design· Maximum efficiency of separation· Cost-effective· Superiority of design confirmed by Computational Fluid Dynamic Analysis· Minimized turbulence· Engineered tiles are designed specifically for your application· Long lasting wear surface· Reduced energy usage

The material cyclone suffered serious abrasion and impact when it separated the material particle, like coal, gold, iron and ext. because of high speed material conveying. It’s very easy to wear out to leak the material from cyclone and a suitable wear protection solution for material cyclone is very necessary.ULTRAMING used the ceramic liners lined into the inner wall of the cyclone to get the wear & impact protections. It has been turned out it’s a very good wear solution for material cyclones.Also, we can design different shape and thickness ceramic liners for the cyclones according to different working conditions. Custom cyclone can be made according to client’s drawing.Applications:·Coal·Mining·Cement·Chemical·Steel

The material cyclone suffered serious abrasion and impact when it separated the material particle, like coal, gold, iron and ext. because of high speed material conveying. It’s very easy to wear out to leak the material from cyclone and a suitable wear protection solution for material cyclone is very necessary. ULTRAMING used the ceramic liners lined into the inner wall of the cyclone to get the wear & impact protections. It has been turned out it’s a very good wear solution for material cyclones.Also, we can design different shape and thickness ceramic liners for the cyclones according to different working conditions. Custom cyclone can be made according to client’s drawing.Applications:· Coal· Mining· Cement· Chemical· Steel

Material of Cyclone liner 1. Alumina2. RBSiC silicon carbide3. ZTA Dimensions can be customized by client’s request. Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment. Product Introduction: Seperator cyclone equipment is mainly abrasive damaged by handling material, QMX can design ceramic cyclone liners according to customer's cyclone size and wear resistance requirement. ceramic tile liner cut and then composed . Product Application: Apart from the standard alumina ceramic tile, we can also manufacturer the pre-engineering ceramics to suit different equipment. We have our technical team who can help the client to choose the suitable wear resistant ceramic products ,and also we have the ability to design and make the CAD drawings according to the client’s wear application. The Tailor-made ceramics had the advantage of low wear, high hardness and impact resistance , it widely used for the chutes, hoppers, bunkers , pipelines in the mining, power generation, steel plant, steel plant industries, it make cost effective performance and reduce the maintenance cost and down-time for the clients.