and Wear Resistant Products

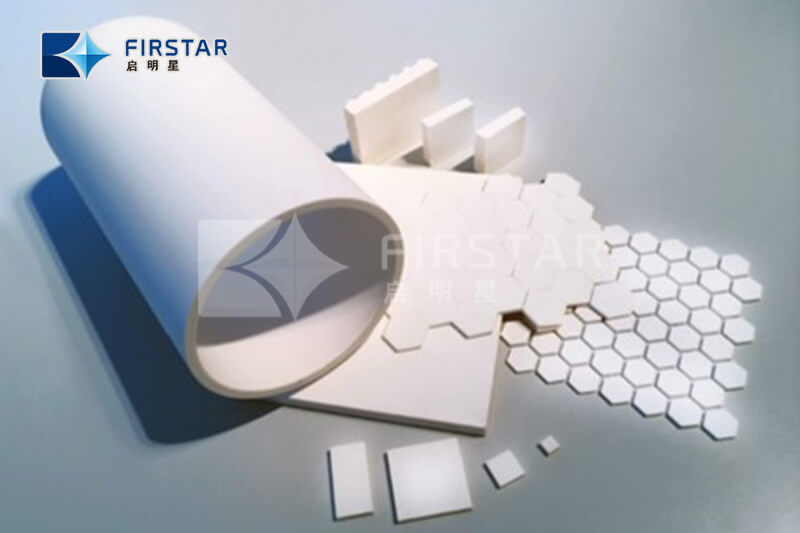

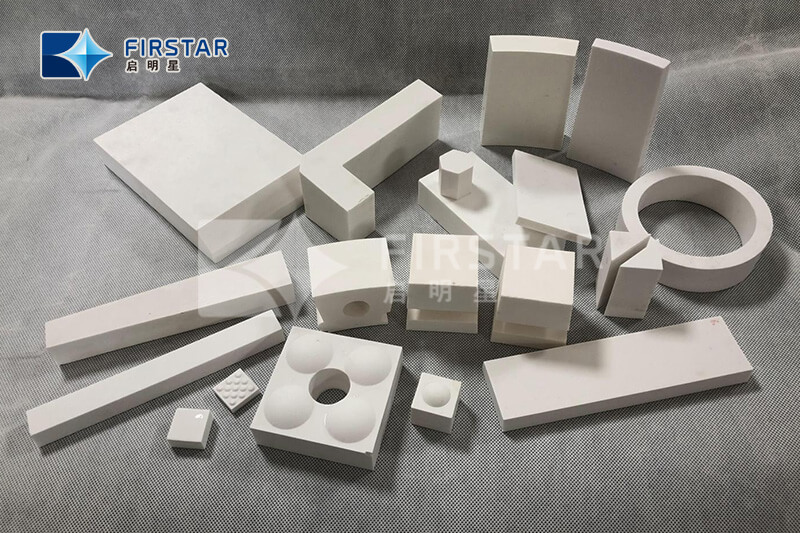

ONLY DIAMONDS ARE HARDERFor aluminium oxide ceramics, ceramic raw materials with an Al 2 O 3 content of more than 80% are used (as high-quality wear protection, in general only ceramics with an Al 2 O 3 content of at least 92%) should be used).It is essentially a single-phase, single-component oxide of corundum crystals, which are bonded by solid-state reactions during sintering.Aluminium oxide is one of the hardest engineering materials and currently the most technically and economically important representative of oxide ceramic materials.Densely sintered it is characterized by:• High degree of strength and hardness• Resistant to high temperatures and corrosionMANUFACTURE AND PROPERTIESThe starting point for the production process is a very pure, synthetic (alpha) aluminium oxide in powder form. The higher the Al 2 O 3 content, the better the mechanical values and the lower the glass phase will be. This leads to an even higher density and to a higher wear resistance.The casting process:• Pressing (highest wear resistance)• Slip casting (demanding geometries)These processes produce the so-called “green bodies” whose consistency is similar to that of chalk. They can now be machined with conventional machines by turning or sawing to obtain specific contours or dimensions. The subsequent sintering process takes place at approximately 1560°C, after which the parts are connected and no longer have any porosity. The resistance values remain virtually unchanged up to 1000°C.APPLICATIONSDue to their high hardness and temperature resistance, aluminium oxide ceramic products are used in extreme wear conditions, often associated with high operating temperatures. The availability in very low wall thicknesses makes thin-walled wear protection coatings possible, especially where weight or construction restrictions prevent the installation of a thicker wall thickness.The wide variety of products allows the coating of all parts subject to heavy wear and high temperatures, such as separators, bunkers, diffusers, sprayers, hydrocentrifuges, chain conveyors, cones, mixers, pumps, chutes, pipes, chutes, gutters or cyclones.

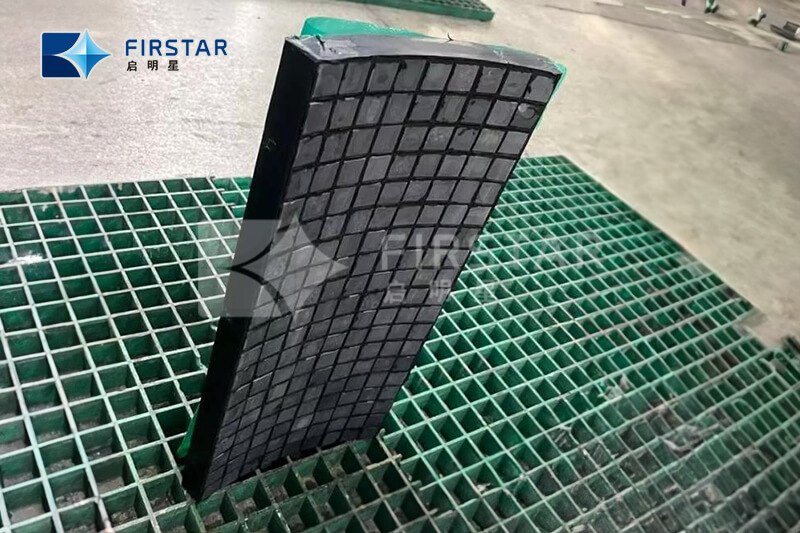

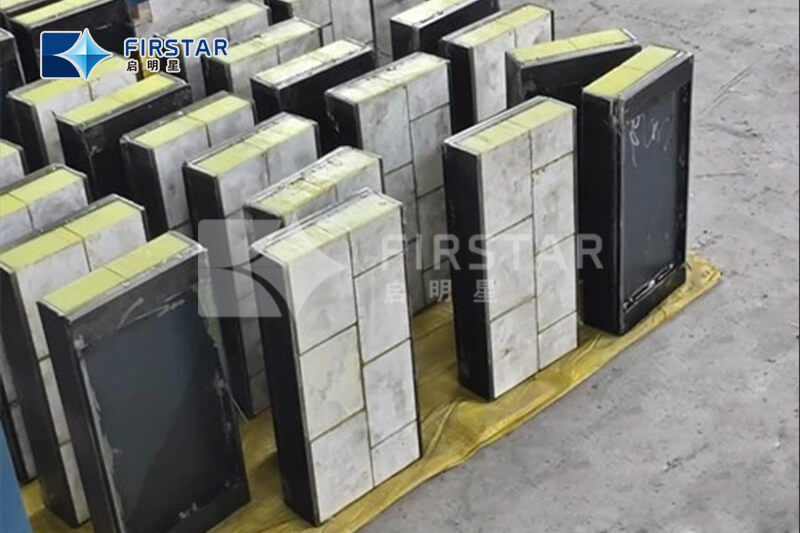

The next generation in ceramic wear liners are the ZTA liners, offering the ultimate in abrasive resistant high-density zirconia toughened ceramic. The ZTA ceramics are vulcanized to a rubber bed and steel plate suitable for stud welding. They offer an increased lifetime of more than 2.5 to 3 times more than standard ceramic liners, plus a significant increase in impact resistance, which make ZTA liners an ideal solution for problematic applications where traditional liners struggle. Features The zirconia toughened alumina tiles used to create Vulcabrix ZTA ceramic composite gives these wear liners increased resistance to cracking when compared to conventional alumina tile based liners. The ZTA liners also offer improvements in weight management due to their lower density than metallic liners. As well as welded studs for quick and easy attachment, Vulcabrix ZTA offers custom shapes, bevels and edge protection. Manufacture An alumina powder is blended with zirconia powder at a precise ratio before the tile is pressed into the desired shape. The zirconia addition gives the tile increased impact resistance when compared to typical alumina tiles. After pressing the powder into a mould, sintering at 1500-1600°C binds the powder particles together creating a solid tile. The tiles are then attached to a steel backing plate using controlled heating and pressing, rubber vulcanization process cycle. The rubber provides cushioning to the tiles whilst allowing for the flexibility of attachment methods to the backing plate. The liner is then ready for post-processing and use in extremely abrasive environments involving moderate to high impact. Product Features: Customized Liners Maximum Resistance to Abrasion Reliable Adhesion Strength Impact Protection Edge Protection Noise Reduction Supply Benefits: Typical Properties Hardness ≥1300 HV20 Open Porosity <0.1% Ceramic Density 4.2g/cm3 Rubber Hardness 55~60 Shore A Tile Thickness 50mm,25mm & 20mm Liner Thickness 112mm, 63mm, 37mm & 32mm Applications Include Deflector/impact plates Skirt Liners Bins and hoppers Chutes Launders

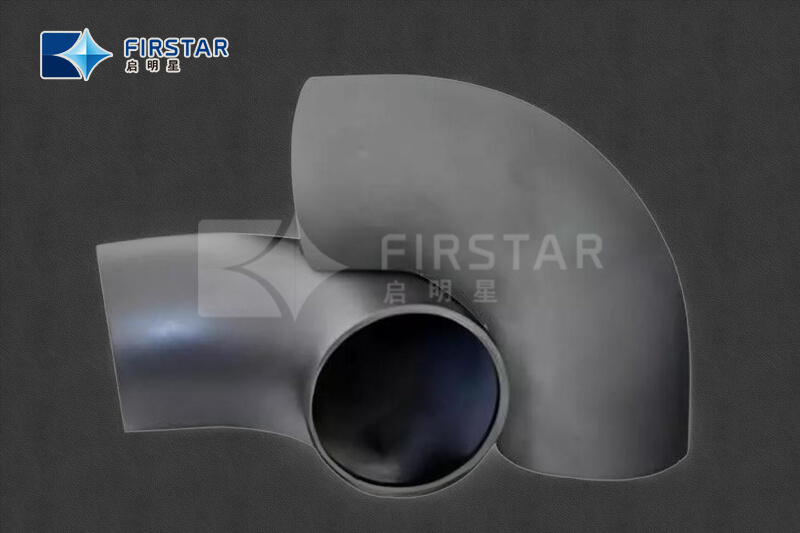

THE IDEAL SOLUTION FOR COMPLICATED WEAR PROTECTION APPLICATIONSSilicon carbide ceramic is distinguished from other wear protection materials in particular by its very high resistance to temperature fluctuations. Therefore, it is used both as protection against abrasive wear and shock wear at extremely high operating temperatures and at the same time strong and rapidly successive temperature changes.MANUFACTURE AND PROPERTIESAccording to the material classification for ceramic materials, silicon carbide ceramic belongs to the group of ceramic materials composed of non-oxides.There are two types available:• The starting point is high-quality raw materials of silicon carbide, silicon dioxide (SiO 2 ) and aluminium oxide• Special quality due to a bond of silicon nitride (Si 3 N 4 )SiC granules are mixed with temporary and permanent binders. Production takes place in a dry, semi-dry or compression process. Moulded parts are produced after the casting process, followed by a sintering process.Features:• Excellent resistance to temperature fluctuations• High temperature resistance• High hardness• High thermal conductivity• Resistance to corrosion• Max. operating temperature up to 1400°C, depending on qualityKey Material PropertiesITEM:UNIT:DATA:TemperatureCelsius1380 cDensityg/cm³3.1 – 3.2Open porosity%≤1.56 – 1.66Bending strengthMPa250 ( 20 c )MPa280 ( 1200 c )Modulus of elasticityGPa330 ( 20 c )GPa300 ( 1200 c )Thermal conductivityW/m.k45 ( 1200 c )Coefficient of thermal expansionK-1 x 10-64.5Rigidity13Acid proof alkalineExcellentStandard ToleranceFlatness≤ 0.2%Thickness+ / – 1.0 mmLength / Width+ / – 1.5 mmKey ApplicationsReaction Bonded Silicon Carbide for Kiln Furniture and Support Components– The high temperature strength, oxidation resistance and thermal shock resistance of Reaction Bonded SiC enables the manufacturer of low mass kiln supports. Kiln products include thin walled beams, posts, setters, burner nozzles and rolls. The components lower the thermal mass of kiln cars, result in energy savings and provide the possibility for faster product throughput.Reaction Bonded Silicon Carbide for Wear Parts and Thrust Bearings– Wear resistance, high temperature strength and corrosion resistance make Reaction Bonded SiC an ideal material for wear components, such as screws, plates and impellers. It can also be used in thrust bearings that can carry extremely high loads in heavily contaminated liquids.Reaction Bonded Silicon Carbide for Mechanical Seals and Vanes– Reaction Bonded SiC can be used in mechanical seals and pump vanes with high abrasion resistance.Reaction Bonded Silicon Carbide for Precision Components– The negligible volume change after reacting with liquid silicon means that components can be formed with complex shapes and to exacting tolerances. The components are lightweight and stiff with excellent thermal stability.

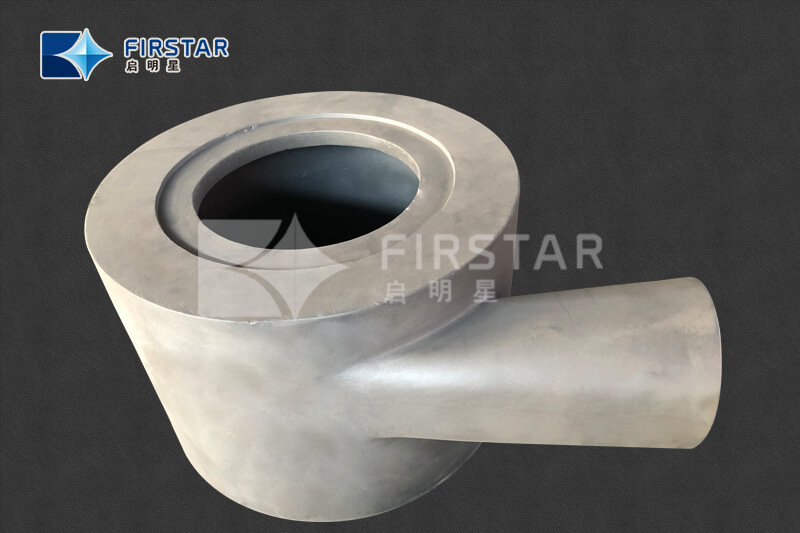

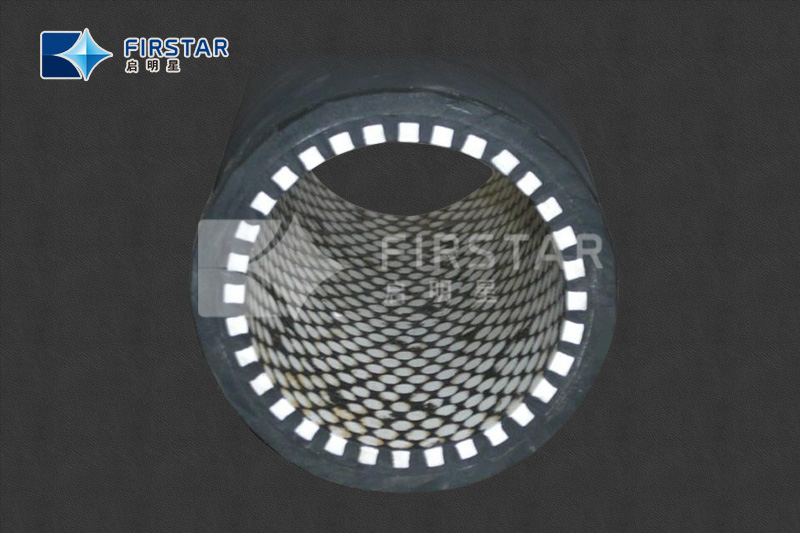

Ceramic Lined OrificesProduct DescriptionIndustrial Ceramics is dedicated to manufacturing hi-tech ceramics for industrial applications. QMX Specialize in the manufacture of wear limiting products, grinding media, liners and engineered ceramics catering to the critical and demanding applications in the Armour, Ceramic Tile, Non-Ferrous, Steel, Power Generation, Power Distribution, Cement, and Mineral & Ore Processing.For pipeline applications requiring precise measurement of volumetric rate or predictable, smooth, QMX offers customized ceramic lined orifice that are more wear resistant than traditional stainless steel orifices. Our Ceramic orifices feature a fabricated steel housing that installs between pipe flanges to securely support the ceramic flow element using a tough, high-adhesion natural and synthetic rubber compound specially selected for the operating environment. Our housings can be configured to fit between flanges of any specification, and are available in stainless steel when required .Fine Grained, high alumina content ceramic offers the best abrasion resistance of any commercial material in metallurgical slurry applications. QMX can choose from a variety of ceramic bodies to find the material with the best properties for each application. To ensure the highest density and dimensional accuracy, the ceramic material is isostatically pressed before machining and firing, The result is a dense, abrasion-resistant and dimensionally accurate orifice.Alumina Ceramic Orifice are the integral part of Variable orifice, Static orifice, Feed Orifice etc. Ceramic Orifice are used to avoid the unwanted punchers and unnecessary downtime for the conveying operations. CUMI designs, manufactures, and supply Alumina Ceramic Orifice for the wear, corrosion and abrasion resistance application. Ceramic Orifice are designed with special dove tail design to ensure to avoid the dislodging of tiles from the steel surface.Ceramic Orifice Benefits:• Longer life of steel structure of the Ceramic Orifice• Prevention of the unwanted punchers• Prevention of frequent maintenance• Less frequent Ceramic Orifice changeoverMaterial Type:- 92%, 95%, 96%, 99% alumina - ZTA(zirconium Toughened Alumina)- RBSiC (Reaction Bonded Silicon Carbide) Applications:• Cement Plant• Steel plant• Mining• Coal based thermal power plantsFeatures:• High strength• Fine finish• Accurate dimensions

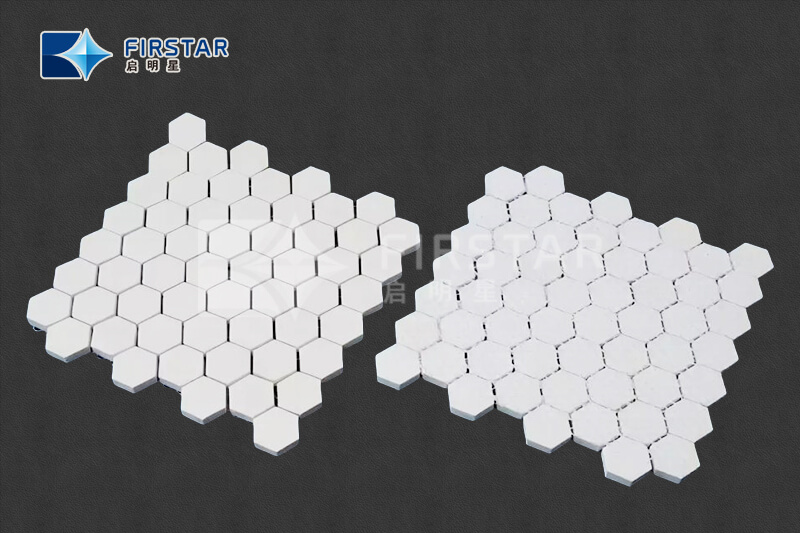

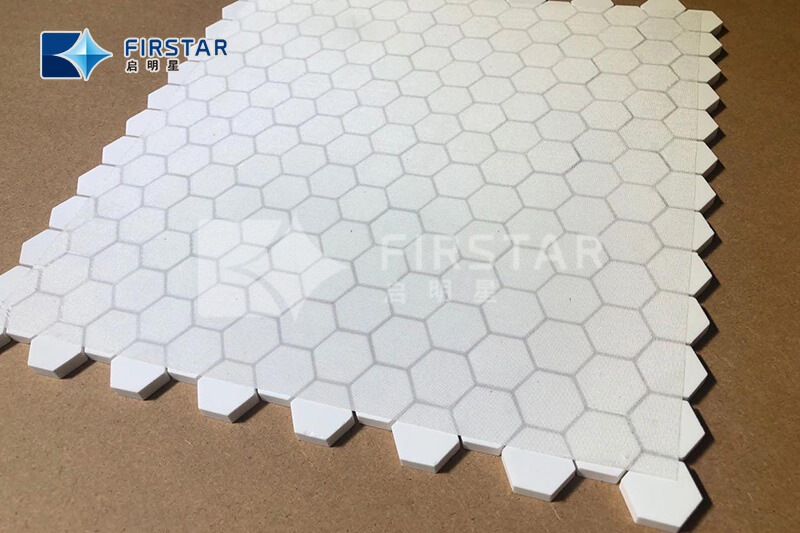

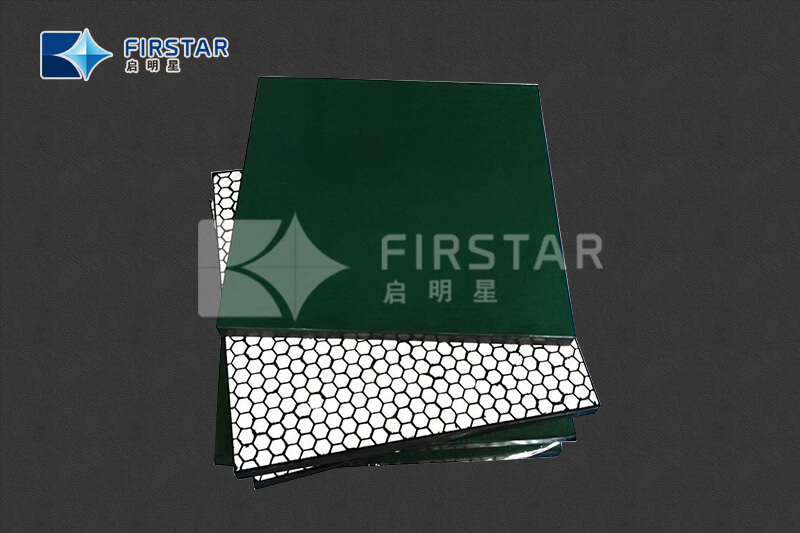

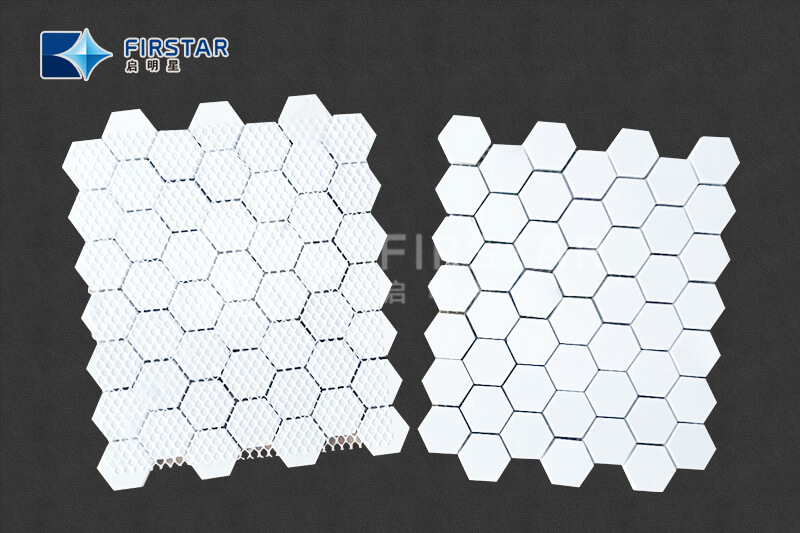

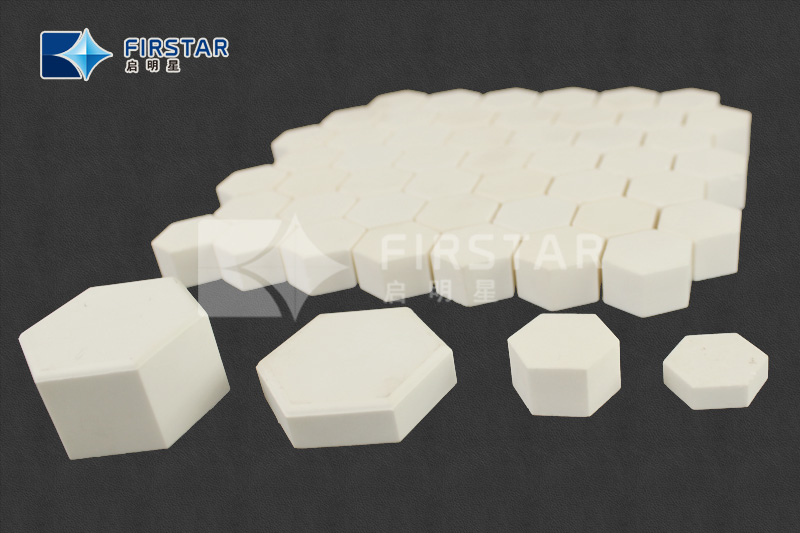

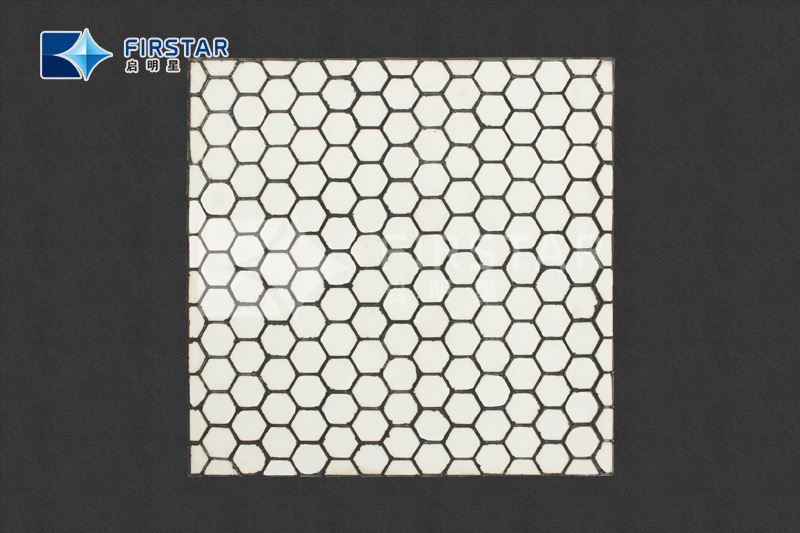

Hex Ceramic Tile Lining KitAbrasion resistant liningOur Alumina abrasion resistant ceramic linings are highly durable and have a significantly longer lifespan compared to lower grade materials typically used for lining or protecting processing and material handling equipment. These linings can outlast these lower grade materials by factors ranging from 3 to 15 times.One common application for our Alumina ceramic linings is in grain transitions. These transitions are areas where grains are moved from one section to another, and they are prone to wear and tear due to the abrasive nature of the grains. By using our ceramic linings, these transitions can be protected and their lifespan can be extended. Similarly, grain spouts, grain elbows, and grain chutes are also susceptible to abrasion and deterioration. Our Alumina ceramic linings provide excellent resistance against wear, allowing these components to withstand the constant flow of grains without experiencing significant damage. This greatly reduces the need for frequent replacements and maintenance. Grain conveyors, hopper bins, and grain valves are other critical equipment in the grain handling industry that can benefit from our ceramic linings. These components are exposed to high levels of abrasion and impact as grains are transported and processed. By installing our Alumina ceramic linings, these equipment can be protected from wear and damage, resulting in improved reliability and reduced downtime. Overall, our Alumina abrasion resistant ceramic linings offer superior longevity compared to lower grade materials commonly used in the industry. By choosing our ceramic linings, businesses can significantly reduce maintenance costs, minimize equipment downtime, and extend the operational lifespan of their processing and material handling equipment. Technical SpecificationsCeramic Material: High Alumina Fine-grain AluminaSurface Finish: As-FiredDimensional Tolerance: ± 1~1.5%Dimension Available: 150x150mm | 300x300mm |300*500mm|500*500mmCategoryHC92HC95HCT95HC99Al2O3≥92%≥95%≥95%≥99%ZrO2////Density (gr/cm3)>3.60>3.65g>3.70>3.83HV 20≥950≥1000≥1100≥1200Rock Hardness HRA≥82≥85≥88≥90Bending Strength MPa≥220≥250≥300≥330Compression strength MPa≥1050≥1300≥1600≥1800Fracture Toughness (KIc MPam 1/2)≥3.7≥3.8≥4.0≥4.2Wear Volume (cm3)≤0.25≤0.20≤0.15≤0.10Alumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkali resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel. Advantages:1. High hardness, its Rockwell hardness is HRA80-90, the hardness is second only to diamond2. Long service life, under the same working conditions, the service life of the equipment can be extended by more than 10 times.3 Light weight, its density is 3.6g/cm3, which can greatly reduce equipment load.4. The bonding is firm and the heat resistance is good. The hexagonal ceramic tile mat is pasted on the inner wall of the equipment with heat-resistant super glue.Application:Widely used in anti-wear material conveying systems in coal, thermal power, steel, cement, mining, port, chemical and other industries, such as coal washing plants, thermal power plants, coal pipes, coal hoppers; coke hoppers in steel plants; mining transfer hoppers; cement plant clinker, cement chute, hopper.

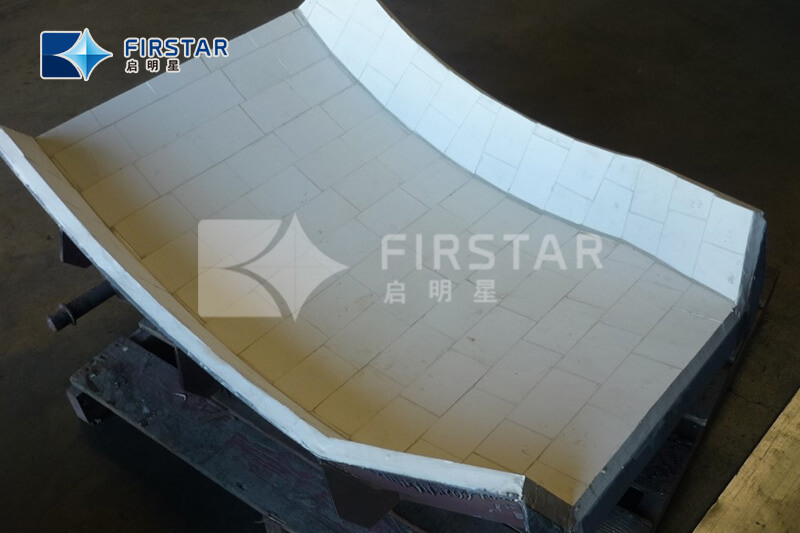

Hex Ceramic Tile Lining KitCeramic liners provide long lasting solutions to the problems caused by abrasive wear and corrosion in a variety of hostile environments.Our Alumina ceramic linings will outlast lower grade materials commonly used to line or protect processing and material handling equipment by factors of 3 to 15 times. Tile linings are often used in grain transitions, grain spouts, grain elbows, grain chutes, grain conveyors, hopper bins, grain valves and grain gates.For use on Curved Surfaces where flat tiles will not work.Dimensions: 6" x 6" Mats,12"x12"mats ; 1/8", 1/4" , 1/2" ,1" ThickPrices are Per MatTechnical SpecificationsCeramic Material: 90% fine-grain aluminaSurface Finish: As-FiredDimensional Tolerance: ±1.5%Maximum Temperature Limit: 1,500° CAlumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel.Advantages:1. High hardness, its Rockwell hardness is HRA80-90, the hardness is second only to diamond2. Long service life, under the same working conditions, the service life of the equipment can be extended by more than 10 times.3 Light weight, its density is 3.6g/cm3, which can greatly reduce equipment load.4. The bonding is firm and the heat resistance is good. The hexagonal ceramic tile mat is pasted on the inner wall of the equipment with heat-resistant super glue.Application:Widely used in anti-wear material conveying systems in coal, thermal power, steel, cement, mining, port, chemical and other industries, such as coal washing plants, thermal power plants, coal pipes, coal hoppers; coke hoppers in steel plants; mining transfer hoppers; cement plant clinker, cement chute, hopper.

Abrasion resistant liningOur Alumina abrasion resistant ceramic linings are highly durable and have a significantly longer lifespan compared to lower grade materials typically used for lining or protecting processing and material handling equipment. These linings can outlast these lower grade materials by factors ranging from 3 to 15 times.One common application for our Alumina ceramic linings is in grain transitions. These transitions are areas where grains are moved from one section to another, and they are prone to wear and tear due to the abrasive nature of the grains. By using our ceramic linings, these transitions can be protected and their lifespan can be extended.Similarly, grain spouts, grain elbows, and grain chutes are also susceptible to abrasion and deterioration. Our Alumina ceramic linings provide excellent resistance against wear, allowing these components to withstand the constant flow of grains without experiencing significant damage. This greatly reduces the need for frequent replacements and maintenance.Grain conveyors, hopper bins, and grain valves are other critical equipment in the grain handling industry that can benefit from our ceramic linings. These components are exposed to high levels of abrasion and impact as grains are transported and processed. By installing our Alumina ceramic linings, these equipment can be protected from wear and damage, resulting in improved reliability and reduced downtime.Overall, our Alumina abrasion resistant ceramic linings offer superior longevity compared to lower grade materials commonly used in the industry. By choosing our ceramic linings, businesses can significantly reduce maintenance costs, minimize equipment downtime, and extend the operational lifespan of their processing and material handling equipment.

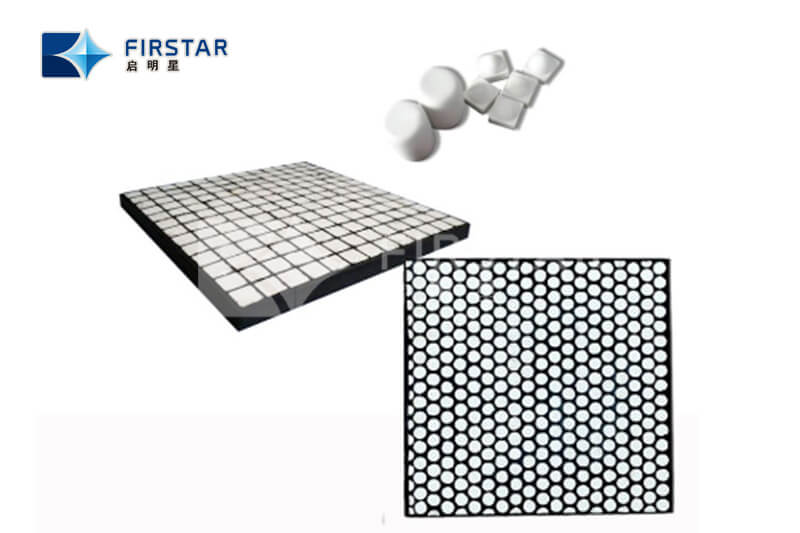

Extremely tough with outstanding wear life properties Vulcanized rubber ceramic liner not only solves ceramic fragile property, but also solve problem of ceramics falling off , so rubber ceramic composite liner steady play its important industrial value. Ceramic wear liners are innovative and high-performance solutions designed to protect industrial equipment and components from the damaging effects of abrasive, erosive, and impact forces. They are a crucial element in industries where materials handling and processing involve the movement of abrasive materials, such as mining, cement, steel, power generation, and chemical processing. Traditional metallic wear-resistant materials have limitations when exposed to severe wear and corrosion conditions. This is where ceramic wear liners prove to be superior alternatives. These liners are made from advanced ceramics, which possess exceptional hardness, toughness, and resistance to wear, making them ideal for demanding applications.Advantages Improved wear lifeCeramic wear plates maximize the lifetime of your equipment, and increase production capacity in both wet and dry applications. Flow improvementImprove poor material flow caused by narrow sectors in the process. Such spots can be real bottlenecks and create a lot of additional work and unplanned downtime. Reduce noise pollutionAll ceramic wear products reduce noise and contribute to a better work environment. Type of Ceramic Material 92% Alumina95% Alumina99% AluminaZTA(Zirconia Toughened Alumina) Zirconium OxideRBSiC Silicon Carbide D3.65D3.72D3.82D4.25D6.10D3.02

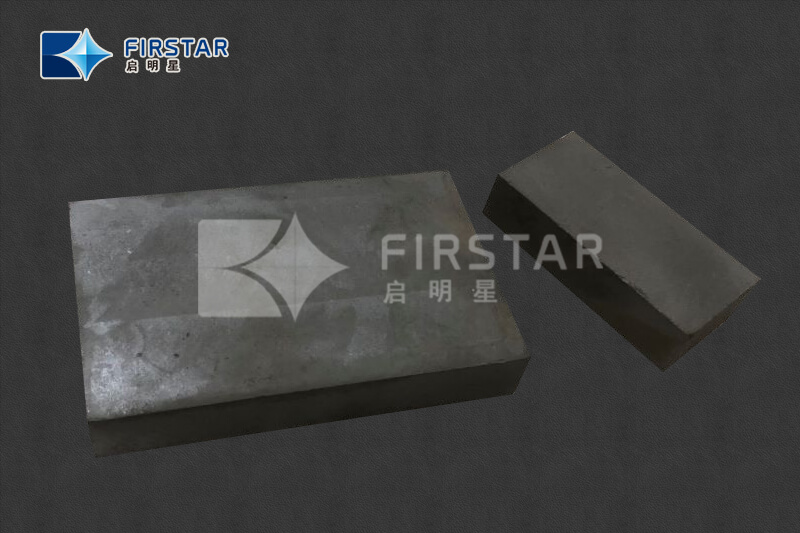

95% zirconia lining bricks are a type of ceramic brick used in industrial applications such as ball mills, attritors, and vibro-energy grinding mills. These bricks are made of a high-purity zirconium oxide (ZrO2) material with a zirconia content of at least 95%.Zirconia lining bricks offer excellent wear resistance and are able to withstand high temperatures, making them ideal for use in harsh industrial environments. They are commonly used in the mining, chemical, and pharmaceutical industries, where grinding and milling of materials is a critical part of the production process.In addition to their excellent wear resistance and thermal stability, zirconia lining bricks also offer good corrosion resistance and are chemically inert, making them suitable for use with a wide range of chemicals and materials.Overall, 95% zirconia lining bricks are a high-performance material that can improve the efficiency and longevity of industrial grinding equipment, leading to cost savings and increased productivity. Technical Data:ZIRCONIA LINING BRICK ITEMSTypical ValuesCompositionWt%94.8% ZrO25.2% Y2O3Densityg/cm3≥6Hardness (HV20)GPa≥11Bending StrengthMPa≥800Fracture ToughnessMPa.m1/2≥7Rock HardnessHRA≥88Wear Ratecm3≤0.05SpecificationCustomizedProject Case

95% zirconia tile is a type of ceramic tile that is made from zirconium dioxide (ZrO2) with a zirconia content of 95%. Here are some of its key features:1. High hardness and wear resistance: 95% zirconia tile has a high Mohs hardness of around 9, which makes it highly resistant to wear and abrasion. This makes it ideal for use in high-traffic areas or where there is a lot of foot traffic.2. Chemical resistance: Zirconia is highly resistant to chemical corrosion and can withstand exposure to acids, bases, and other corrosive substances. This makes it ideal for use in industrial settings or where there is a high risk of chemical exposure.3. Low thermal conductivity: Zirconia has a low thermal conductivity, which means it is an effective insulator. This property makes it ideal for use in high-temperature environments, as it can help to prevent heat loss.4. High fracture toughness: Zirconia has a high fracture toughness, which means it is highly resistant to cracking and chipping. This makes it ideal for use in areas where there is a high risk of impact or mechanical stress.5. Aesthetic appeal: 95% zirconia tile has a smooth, polished surface and a high level of translucency, which gives it an aesthetically pleasing appearance. It is available in a range of colors and finishes, making it a popular choice for use in interior and exterior design applications.Zirconia CERAMIC SPECIFICATIONSZirconium Oxide ZrO294.8 % (min)Density (g/cc)6.05 (min)Hardness (HRA)88 (min)Flexural Strength (Mpa)800 (min)Abrasion Abrasion(cm3)0.05 (max)

ceramic wear resistant linings· Flat ceramic tiles of various dimensions and thickness.· Pre-engineered pipe ceramic tiles.· Interlocking tilesother specialized ceramic products· Monolithic and sets· Pre-engineered inserts and sets· Ceramic tiles and related products used by AVIOCEAN GLOBAL are made to very specific specifications and maintain a high grade of no less than 92% alumina content which is wear resistant ceramic tiles. It counters moisture and creep sulphide attack. Tiles are embedded into an epoxy adhesive applicable to the application.· This lining increases the life span of steel and related products which are subject to severe erosion. Tiles are available in various dimensions and thickness, as required by each application. Pre-engineered ceramic tiles are also available for piping of various diameters and specialized pre-engineered sets for cyclones and similar applications.

Ceramic/rubber lining material is a composite construction of highly wear-resistant 92 %-Al2O3 ceramic tiles (square, rectangular or hexagonal „SW“) vulcanized in special rubber with CN bonding layer.Properties• CN bonding layer provides fast and longlasting adhesion• Highest abrasion resistance• Reduces operating costs• Long service life increases the efficiency of your equipment• Good resistance against weatherArea of application• Lining against extreme wear through abrasion at high speeds• For simple to medium duty applications in mining, gravel, sand and stone breaking mills and other industrial sectors• In applications like pipelines, vibratory feeders, cyclones, skips, bunkers, chutes, loading points, slides, hoppers, silosSpecificationsPolymer basisNR/BR/SBRDIN ISO 1629Specific weight1.12 g/cm³DIN EN ISO 1183-1Hardness62 Shore ADIN ISO 7619-1ColourBlackRef. No. DesignationDimensionsDimensions of ceramic tilesWeight539 9022 10/4 14 x 500 x 500 mm10 x 20 x 20 mm10 kg539 9039 25/15 40 x 500 x 600 mm25 x 100 x 150 mm32 kg539 9046HEX 6/6 12 x 510 x 525 mmSW 32 x 6 mm

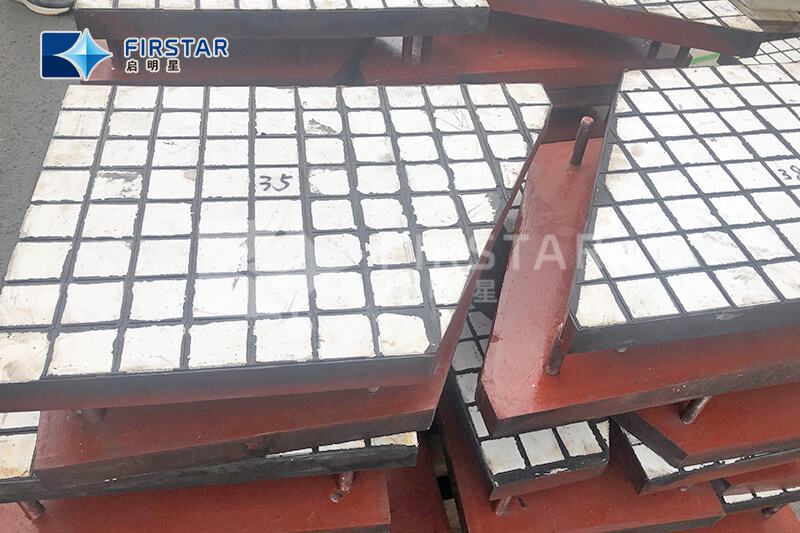

QMX Wear PlateIncrease the life and performance of your operational assets.Wear Plates are designed and manufactured for their specific intended application, ensuring the correct plate is always recommended and installed. In addition to the sale of wear plates, HICTECH offers installation capabilities which deliver exceptional customer satisfaction and value. Facilitated by our experienced and reliable onsite service division, we will take control of your whole project, from the conception and evaluation stage, through to the manufacture, delivery, installation, maintenance and ongoing after sales service/support. Wear plates are engineered to suit each application and have various fixing options, steel studded backing plates, weld on options and direct substrate bonding.Wear PlatesWear Plates are manufactured to the highest quality standards and specifications, making them far superior to any other product in the market.Features:Superior wear characteristicsDampens impactNoise reductionReduces downtimeLow cost per tonne ROIFit for purposeApplications:ChutesHoppersTransfer pointsCrushing and screeningMillingTrain and ship loadersCompositionThicknessesTypeZirconia Toughened Alumina37mm-63mmVulcanised rubber / studded steel plateAlumina 92% / 95% Al20337mm-63mmVulcanised rubber / studded steel plateAlumina 92% Al203 / Natural Rubber8mm-63mmHexagonal, cubed, cylinder, tileAlumina 92% Al203 / High Tensile Polymer10mm-63mmHexagonal, cubed, cylinder, tilePolyurethane3mm-20mmComplete cast

Engineered CeramicsQMX Premium Alumina|Ceramic Wear Lining Tiles for Various Abrasion Application QMX Premium Engineered Ceramics provide excellent impact and wear resistant characteristics for superior longevity in the harshest applications. ManufactureQMX premium alumina products are manufactured to ISO9001:2015 with high purity ultra-fine powders, using the most advanced technologies and international best practice. QMX integrates research, design and manufacturing to produce the highest quality products that provide excellent impact and wear resistant characteristics for superior longevity in the harshest applications.QMX premium alumina ceramics provide maximum protection for applications such as transfer chutes, sumps, centrifuges, screens, cyclones, pipes, bins, hoppers and pulley lagging across various industries. Aluminas (aluminum oxide, Al2O3) are the most commonly used technical ceramics for both general use and specialised applications. Grades are selected to fit the application environment. Alumina compositions and microstructures can be formulated to meet the specific performance requirements of more demanding applications.QMX premium alumina ceramics are manufactured by blending and mixing specified ratios of high-quality raw materials such as alumina powders, oxides, lubricants, dispersion agents, binders and water using a ball mill method. The slurry then goes through a spray drier before the pressing stage. Low percentages of organic binders allow the alumina particles to bond together and form a green un-sintered body during the pressing stage. Once pressed to size, pre-heating takes place followed by sintering through a tunnel kiln. Sintering temperatures and times are strictly followed to ensure binder burn out is optimised and that explosive spalling does not take place.HardnessAlumina ceramics are very hard wear-resistant material with a Mohs hardness of 9 (compared to diamond which is 10), making it an ideal and cost effective material for wear protection components. QMX Alumina’s are manufactured in a range of shapes and sizes in both 92%, 95% and ZT Alumina. The properties of alumina are further enhanced via the addition of densification aids that make up the other 5%-8%. QMX Premium Zirconia Toughed Alumina (ZTA) has a unique crystal structure which combines extreme strength, high fracture toughness, and excellent wear resistance. It is ideal for extreme mechanical environments, particularly impact prone applications.Features:Pre-engineered shapesAbrasion resistanceTemperature resistanceImpact resistanceHardness and durabilityCorrosion resistanceVarying gradesQuality assuredUsabilityMarkets:Coal handling plantsSteel millsIron ore beneficiation plantsHard rock concentratorsPower generationPortsAppliancesLaboratoriesConveyorsCompositionThicknesses/DiameterTypeZirconia Toughened Alumina25mm-50mmStd tile sizesAlumina 92% / Al2033mm-75mm pre-engineeredStd tiles, half tiles, pipe tiles, hex matts, pulley lagging tiles, monolithic sleeves, cylinders, cones, tile setsAlumina 95% Al2033mm-50mmStd tile sizes, half tiles, pipe tilesReaction Bonded Siliconized Silicon Carbide (RBSiC)5-50mm pre-engineeredStd tiles, monolithic sleeve, cylinders, cones, tile sets

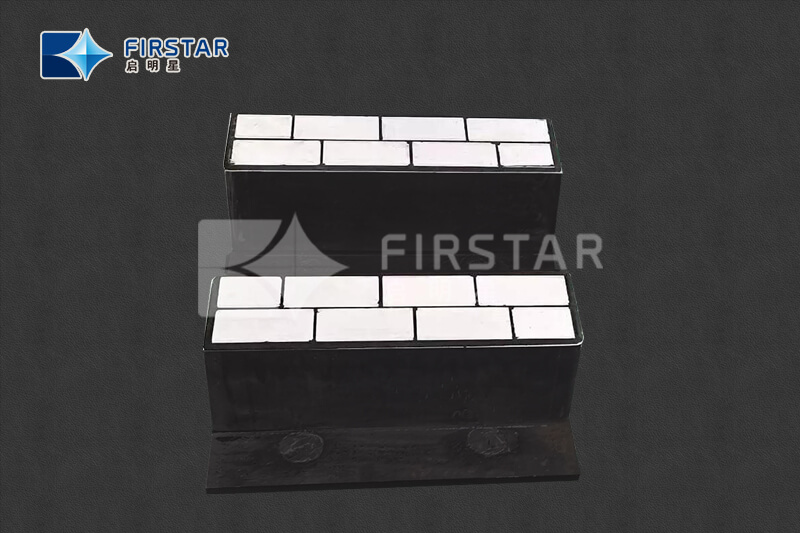

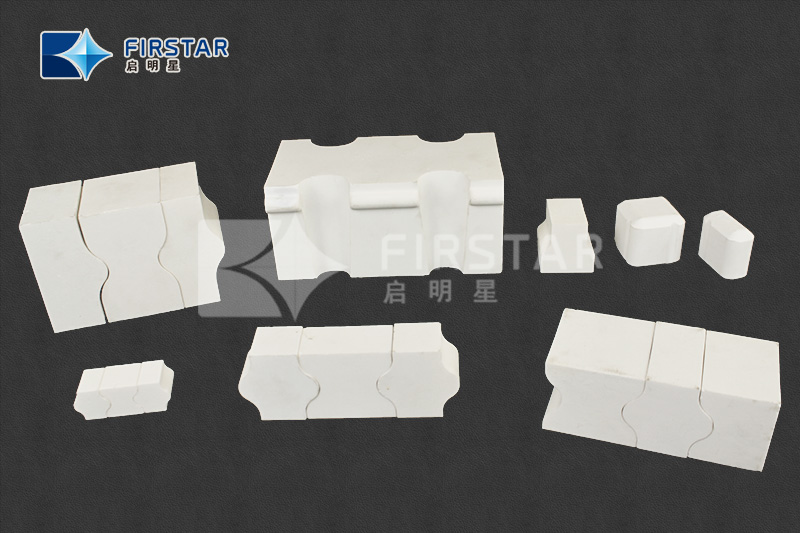

LinerAlumina LinerApplication :The alumina lining bricks are used as the lining in the ball mill of ceramic industry, insulator industry. Using this liner will effectively improve grinding efficiency, reduce grinding cost, and it is considered to be your best choice.Alumina Liner for Batch Mill and Continuous Mill: Standard thickness 40 to 90 mm. with Al2O2 content 92 to 95%.Industry : Ceramic & Insulator Specification of Ball Mill Brick:NameLength (mm)Width 1 (mm)Width 2 (mm)Thickness(mm)40~90mm Thickness Lining BrickRectangular Brick150±250±150±140/50/60/70/77/90±1Trapezoidal Brick150±250±145±140/50/60/70/77/90±1Half Rectangular Brick75±150±150±140/50/60/70/77/90±1Half Trapezoidal Brick75±150±145±140/50/60/70/77/90±1Flake Brick150±225±122.5±140/50/60/70/77/90±1Special Specification Lining Bricks80x50x5555±250±150±180±1110mm Ling Brick75±145±141±1110±2110mm Half Ling Brick37.5±145±141±1110±2Brick for Manhole and Drain-holeThe specification can make according to the customers' requirements.Ball mill liner product pictures:

Conveyor Chute Wear Resistant Ceramic Rubber Liner is made of high alumina ceramics and high-quality natural rubber compounded by a special process. DescriptionThe Conveyor Chute Wear Resistant Ceramic Rubber Liner is made of high alumina ceramics and high-quality natural rubber compounded by a special process. The excellent shock absorption properties of natural rubber help to achieve a certain impact resistance, thereby preventing the tiles from cracking in the high impact area, which has a very superior effect compared with the ceramic lining tiles directly bonded to the steel plant. Compared with wear-resistant steel, the characteristics of high-quality Conveyor Chute Wear Resistant Ceramic Rubber Liner make it more resistant to wear and impact. Their service life is much longer than previous wear-resistant lining products, and can last for multiple shutdown cycles without causing serious wear or failure.S.No.MaterialAttributesProperties1Ceramic TilesMaterial92%, 95%, T95%,99%, ZTA,RBSIC2RubberComponentnatural rubber, nitrile-butadiene rubber ,Flame Retardant ,othersDensity~1.4g/cm3Tensile strength at break≥15MpaElongation at break ≥250%Shore Hardness45-65Adhesive between tile and rubber1.2-3.0 MpaAdhesive between rubber and equipment≥3.8 MpaThermal conductivity.(normal temperature)2w/m·kAging period≥15 YearsWorking temperature-50ºC - 200ºC3Steel plateMaterialQ235ADensity7.85g/cm3Thickness5-6mm4AdhesiveAppearanceBrown glutinous liquid Solid content20±3%Viscosity≥2.5 MpaPeel strength48h N/2.5cm≥120Compressive strength≥850 MpaWorking temperature-20ºC - 100ºCApplication of Conveyor Chute Wear Resistant Ceramic Rubber Liner Conveyor Chute Wear Resistant Ceramic Rubber Liner provide wear-resistant linings for various equipment, chutes, pipes, hoppers, dustbins, cyclones, screening equipment linings and other industries.

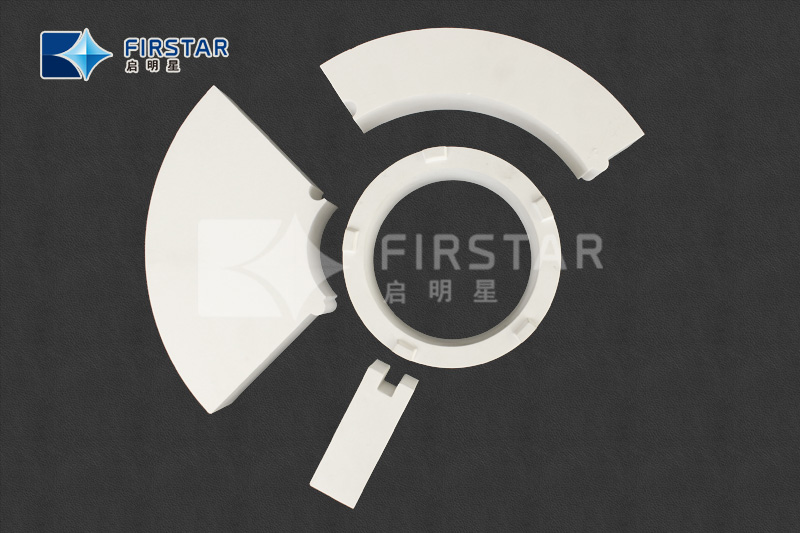

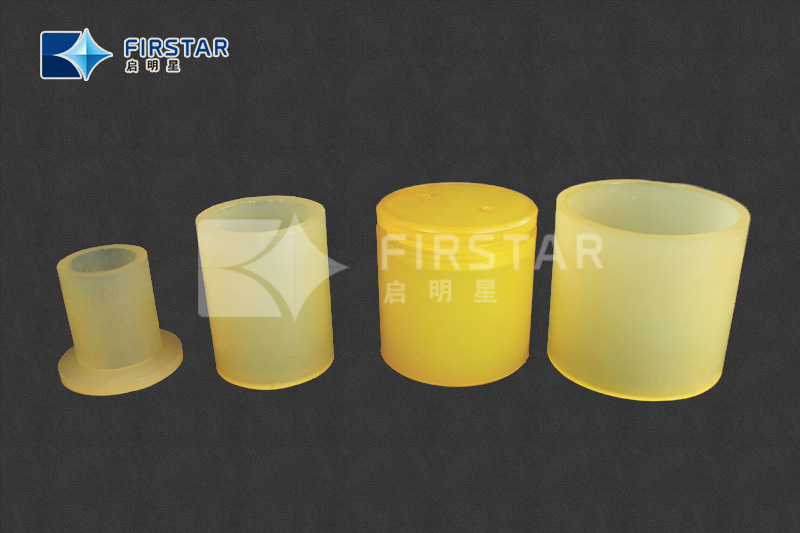

Polyurethane Encased Hydrocyclone Liners QMX’s turn-key solution for hydrocyclone slurry separators and other mineral processing equipment delivers single-sourced, completed encapsulated assemblies in just weeks. Where required, our proprietary silicon carbide based formulations can be cast into complex shapes and then encased in polyurethane in-house, providing ease of installation, crack mitigation and added wear insurance, all while delivering a complete solution from one vendor. The VERKAPSE process reduces both cost and lead time for customers while providing a product with greater overall durability and reliability.All proprietary silicon carbide based materials can be cast into very complex shapes, displaying tight and repeatable tolerances that ensure repeated ease of installation. Expect a more abrasion resistant product than cast steels, rubber and urethanes alone at one-third the weight of their steel counterparts. All offer much higher thermal and corrosion resistance. QMX also produces monolithic drop-in replaceable silicon carbide cyclone and hydrocyclone liners specifically engineered for separating and classifying applications. These ceramic liners are designed for highly abrasive ores including coal, iron, gold, copper, cement, phosphate mining, pulp & paper and wet FGD and are available in sizes up to 60″ in diameter.A variety of highly abrasion resistant ceramic compositions are available, maximizing cyclone life and eliminating high installation costs traditionally found in epoxied tile constructions. This assists both OEMs and single plants in achieving financial performance objectives by optimizing classification efficiencies.QMX supplies either the complete assembly of the hydrocylone or the high wear areas including the bottom apex and spigots. Cones, cylinders, vortex finders and volute feed inlet heads are precision cast for repeatable assembly into your existing hydrocyclone.

Joined using a special process, the Hybrid Liner combines two liner materials and their favorable properties. The interior is made of polyurethane and protects the residual limb and bony structures thanks to its shock absorbing characteristics. At the same time, it ensures optimum pressure distribution across the entire residual limb, both for passive and active generation of the vacuum. The outside of the liner and the integrated vacuum flap are made of silicone, proven in everyday use thanks to its robustness. This is particularly important when the vacuum flap is folded over the inner socket to create an airtight seal for the system. Application: On the subject of abrasion with respect to rubber linings, the following statements must be considered.1- There are two types of abrasion one may encounter, impingement and sliding.2- Impingement abrasion occurs when particles strike the surface of the rubber (or any other surface).3- Sliding abrasion occurs when another surface slides across the rubber.4- In virtually every case the abrasion can be expected to be a combination of impingement and sliding.5- Predominantly impingement abrasion occurs in chutes, sandblast hose and anywhere rebound is observed.6- In the impingement process, particles hit the surface and any stresses produced are distributed evenly if the rubber yields easily, especially when the particles strike at a 90° angle to the surface.

Canoe Liner Benefits QMX has been manufacturing wear liners of all types for over 25years. From Bolt on to weld in, canoe liners or skirting liners, with steel back or ceramic face we can supply all your requirements. QMX manufacture impact and wear resistant liners in almost any size and shape from the highest quality materials specifically chosen for your environment. We can work with your drawings to assist with liner layout and tag each liner for installation to the layout drawing. We can help you map out your wear lining requirements for any size or configuration.

Chute Linings are designed to be an integral part of a conveyor system. Our pre-engineered chute lining protects and cushions the chute from the material being handled; Skirt Liners prevents fugitive materials from escaping and damaging the conveyor loading areas. We can build, design, fabricate and install chutes, and also repair and re-align existing chutes.

Keeping product on the line and off of adjacent walkways and equipment is critical to maintaining a safe and productive work environment. Our tough skirting liners are available in solid rubber or a combination rubber/ceramic matrix, our high wearing skirt liners keep ore in line and protect your equipment, saving time and money while increasing production. Handy Tee slot mounting allows for use in skirting or solid wall wear applications and are interchangeable.Solid Rubber or Ceramic / Rubber with steel backing plate and Tee Bolt slots for easy mounting means the entire wear face is solid with no holes to catch material and cause premature wear or bolt deterioration. Liners can be adjusted easily up or down to achieve the best fit.QMX can supply wear and skirting solutions for all types of material conveyance wear and impact areas. Custom liners are available for specialty applications such as wood and food processing and handling.Examples of Use· Conveyor Skirting· Chutes· Hopper wear areas· Impact protection· Material transfer points· Overhead conveyor lines· Primary impact areas· Rail and Port loading terminals· Rock boxes· Screen Deck protection· Screen discharge areas· Screen undersize chutesFeatures: · Highly effective particularly where material is being bulk loaded onto the conveyor to control the material until it becomes stable.· The liners are steel backed and made to fit existing loading stations.· They are manufactured to conform to the belt with the ability to adjust the height to fit the belt and maximize the liner life.· The rubber thickness varies and ceramics can be added to fit the application.· In load-zones with high tonnage rates, Canoe Liners significantly reduce spillage, dust and wear.· Designed specific to your application, then custom manufactured.· Each metal-backed Canoe Liner comes with the ability to adjust the height to fit your conveyor belt.

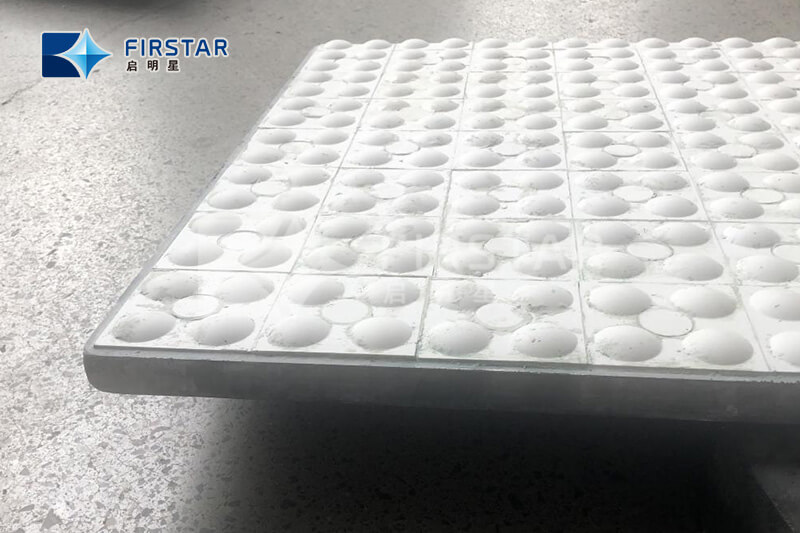

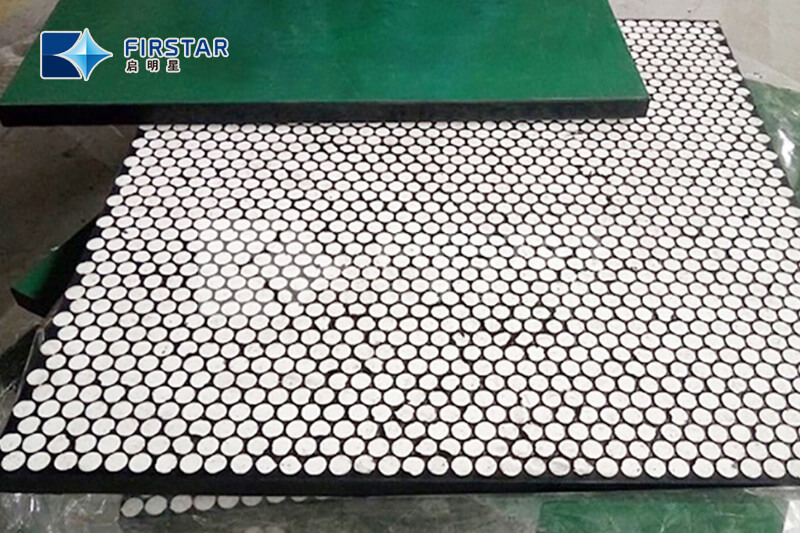

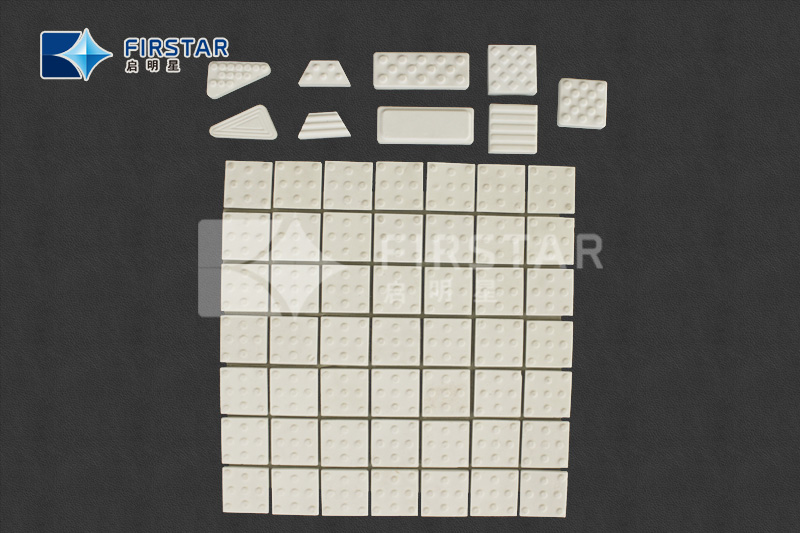

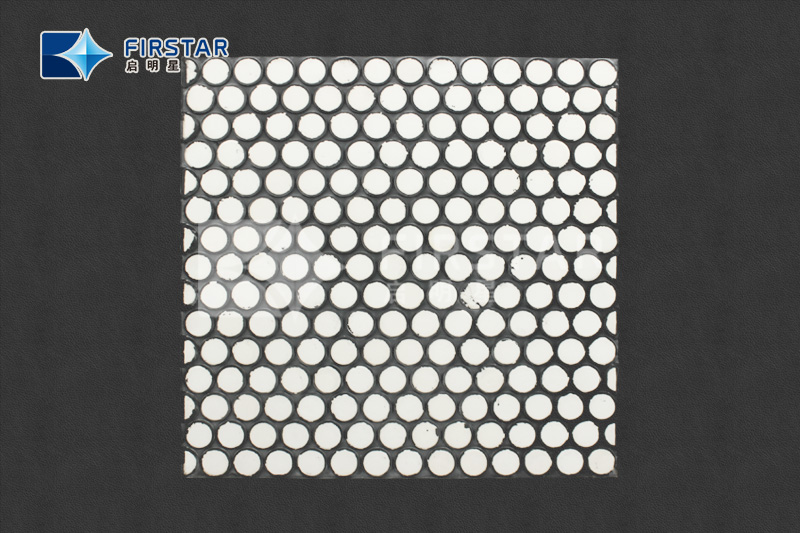

Detailed description:QMX Pulley lagging is made through hundreds of individual ceramic lining pieces vulcanized into durable rubber plates, every applied ceramic lining tile have raised dimples for abrasion resistance.Generally,with the conveying pressure , thousands of salient point in alumina ceramic liner tile can have a positive traction to prevent slipping, extending the life of the roller conveyor.Which makes the drive roller life ten times more than the original drum .At the same time,each ceramic sheet has grooves spaced in a certain distance, enabling foreign matter like dust, dirt on the drum discharged along the trench, which makes the drum with a unique self-cleaning function, especially suitable for wet working environment.Alumina ceramic mosaic tile have various sizes available.Alumina ceramic characters: > High hardness with Moh's hardness 9 grade> High abrasion and chemical resistance> Special dumps designed for more wear resistance> Light weight with various sizes

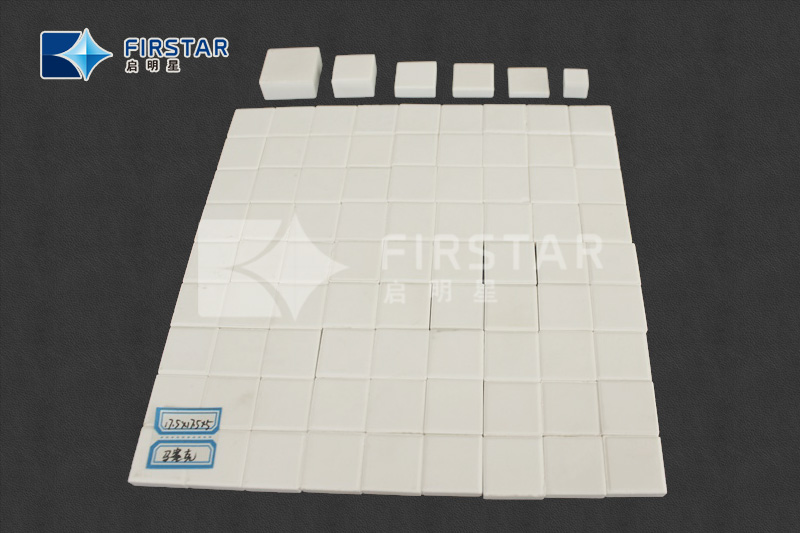

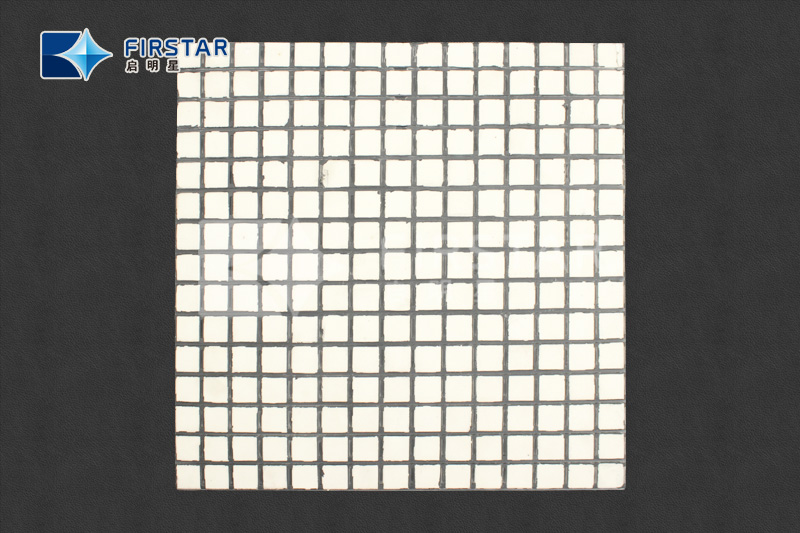

High Alumina Ceramic Tiles Mats Product Description:Alumina Ceramic square tile mats is combination of high hardness alumina mosaic tile and backed silk , paper or net .the low friction , smooth surface prevents materials build-up in low inclination installations. The square ceramic tiles make it possible to bend the sheeting which makes it perfect protection for con-ave and convex surface .the sizes of ceramic square tile matted can be easily be adjusted by bending the sheeting and cutting it in between the ceramic tiles .this alumina ceramic square tile matted has advantages including : no specialist tools required, can be applied to most substrates . Convenient design for fast and easy application .Alumina ceramic tile mats advantages :> High hardness with Moh’s hardness 9 grade> High abrasion and chemical resistance> Easy installation by epoxy resin glue water> Easy mending if someone hex tile drop off> Various of alumina ceramic hex sheet size availableSizes:L*WThk.Ceramic mats(stick on Sticker/nylon Mesh/Acetate/Paper10*103--10mm150*150mm17.5*17.53--15mm150*150mm, 300*300mm,300*500mm20*204--15mm300*500mm25*254--10mm/12*126--25mm/12.5*12.56--25mm/

QMX Ceramic mosaic mat are of 2 shapes, square alumina ceramic mosaic tiles and alumina ceramic hexagon mosaic mat, inlaid on the surface of equipment and work area by rubber or glue. They are designed to protect equipment and work area by abrasion resistance, acid and alkali corrosion resistance and other characteristics. Alumina ceramic mosaic tiles can be used in flat areas and curved surfaces. DescriptionCeramic mosaic mat as wear resistant liner materials and easy fixing process is popular in the field of wear-resistant. It is widely used as wear liner for pulley lagging, rubber ceramic plate and kinds of irregular surface of equipment and facilities. It can be easily installed and fixed by special adhesive. Popular Sizes Of Alumina Ceramic Mosaic Tile MatsPopular sizes of the flat alumina tiles as follows:500*500*6mm 4mm ceramic+2mm rubber500*500*8mm 4mm ceramic+4mm rubber500*500*10mm 6mm ceramic+4mm rubber500*500*14mm 10mm ceramic+4mm rubber500*500*20mm 15mm ceramic+5mm rubber500*500*25mm 20mm ceramic+5mm rubber500*500*30mm 25mm ceramic+5mm rubber Product Features1) Suitable for lining on irregular surfaces2) High strength3) High hardness4) High density5) Acid and alkali resistant6) Corrosion resistant7) Good impact resistance

Product Name:Alumina Ceramic Hexagonal TilesProduct H.S Code:690912Product Materials:AluminaProduct Color:WhiteCertificate:ISO9001Customized:AvailableProduct Packaging:Cartons and Pallet Product Details:QMX alumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel Size of Alumina Mosaic Ceramic ( square / Hex.) Tiles

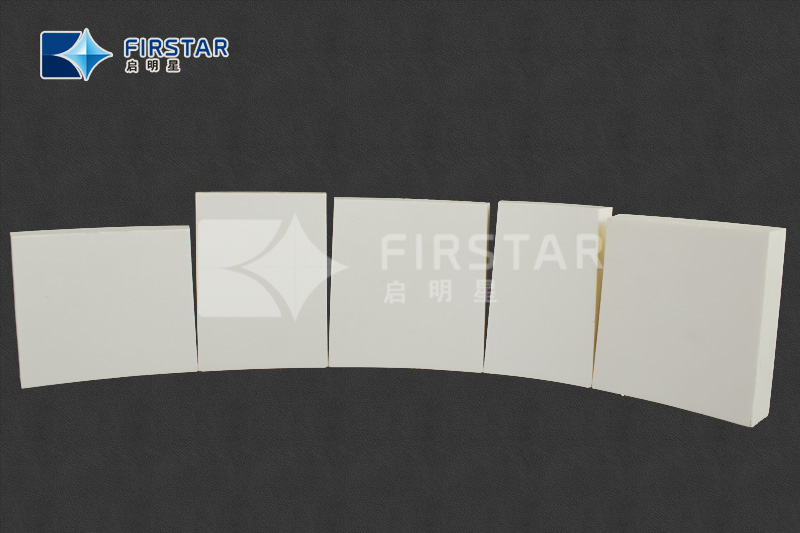

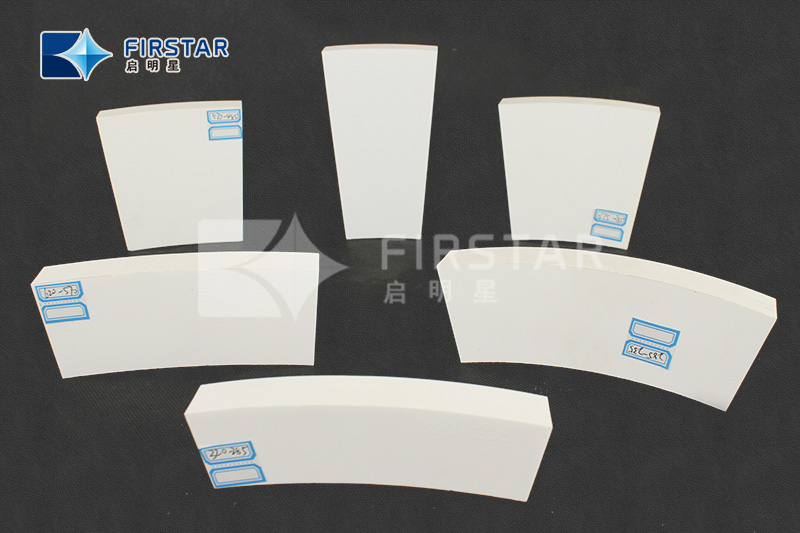

Trapezoidal Pipe Ceramic Lining PlateProduct Introduction:Trapezoidal pipe ceramic lining plate is suitable for wear-resistant lining of pipes and elbows with a diameter of less than 900mm. Trapezoidal lining plates of various specifications can be customized according to the diameter of pipes and elbows, so that they become a complete circular surface during final construction. The board is tightly combined with the board. The wear-resistant ceramic lining plate of the trapezoidal pipe is fired in a tunnel kiln, and the kiln temperature is stable. The fired ceramic lining plate is uniform in color, which has the texture of jade, and the surface is neat and free of black spots.Advantages:Trapezoidal pipe ceramic lining plate has the characteristics of wear resistance, corrosion resistance, high temperature resistance, high impact resistance and convenient construction. It’s the ideal material for surface wear of conveying equipment. It is very safe and reliable to use the trapezoidal pipeline wear-resistant ceramic lining in the occasion of high temperature corrosion, high temperature wear or high temperature erosion.Under the same industrial and mining conditions, its service life is 10 to 20 times of the life of cast stone, wear resistant alloy cast steel, steel plastic, steel rubber and other materials.ItemLengthWidthThicknessAlumina palin Tile50-150mm25-100mm6-50mmAlumina Weld-on tile ( Weldable tiles)50-150mm30-100mm10-50mmAlumina Pipe tile(Trapezoidal)50-150mm20-100mm8-50mm

92% Alumina Wear LiningsAlumina Wear linings are protective covers installed in areas subjected to wear. They are widely utilized in mining, aggregates and cement industries processing hard materials that are tough on equipment. The right wear lining prolong the lifetime of equipment, improve material flow, reduce noise, and thus increase the production capacity. ★Applications Be used in Coal, petroleum, steel, coal fired power generation industries, etc. As the wear-resistant liner to protect the surface of the transport equipment being worn.★FeaturesBeing fired under high temperature, wear-resistance, shock resistance, acid and alkali resistance, its theory wear-resistance is equivalent to 260 times of manganese steel, 170 times of chromium steel, can enhance the life time of equipment.★Size(We could produce as your required)Item(Length)mm(Width)mm(Thickness)mmNote150×1001501006-50Flat tile150×10015010012-20Welding tile with hole100×1001001006.5-15Flat tile10×10 mat10103-10Square17.5×17.5 mat17.517.54-10Square20×20 mat20203-20Square11.55×11.55 mat11.5511.553-10Square12.5×12.5 mat12.512.53-10Square50×5050505-15Flat tile120×80120806-20Welding tile with hole150×601506010-25Flat tile100×81.6/78.510081.6/78.520Curved tile

Ceramics wear resistant· Wear Resistant: Manufactured with fine-grain alumina ceramic which is 12 times more wear resistant than steel· Optimal Arrangement: The exposed ceramic faces are optimally arranged to minimize the base material exposure and extend useful life· Slip Resistant: The embossed ceramic surface greatly improves belt traction· Variety of Options: ceramic tiles are offered in a variety of shapes, sizes, and thicknesses to suit any application Ceramic: 92% & 95% Alumina, RBSiC, ZTAAvailable with square, rectangular, cylindrical or hexagonal,etc.Cushion Rubber/ PU: Superior rubber/PU compound, impact-absorbingConnection: Steel plate and studs / cn bonding layer, both available to suit different types of applicationsThe thickness of complete liner, ceramic and rubber/PU are determined on the basis of application, such as handled material lump size, height of fall, impact angle, etc.

Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Laid out in zigzag and brick pattern, ceramic tiles/cylinders is an excellent feature for handling large material volumes at different angles without developing a wear pattern. As excellent impact and wear resistant material,The panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc. The major applicable industries are Coal fired power plants, cement plants, blast furnace plants and host of other industries which requires high impact abrasion resistant surfaces.Type of CeramicsRubberSteel/Metal 92% AluminaNatural rubberHardness 60 A235A95% Alumina 99% AluminaZTA Zirconia Hex Tile mats Regular sizes:Panel Size300×300,250×250,500×500,600×600mmCeramic size19x19, 21x21, 40x40 Hex tile Alloy Steel Sizealloy steel plate with thickness ranging from 3 mm to 10 mmRubber ThicknessDepends upon the impact stress expected.Remarkmetal+rubber+ceramic / rubber+ceramicplain surface or spherical surface.The steel bolt also available upon requestsPacking:Wooden Crate Ply-Wood Pallet

Rubber Embedded Ceramic Wear Tile Panels alumina ceramics is one of the hardest of all natural substances. Even under extremely abrasive conditions, no material can compete with its extreme hardness and wear resistance. It has exceptional chemical, mechanical, thermal and electrical insulation properties and can be formed into any shape or size with various qualities for specific applications. Ceramic Wear TilesCeramic wear resistant tiles form part of QMX’s range of engineered ceramic solutions. This range of wear solutions provides high-levels equipment protection from material abuses, extending the life of mineral processing equipment in mining, mineral extraction and power generation applications. QMX’s wear-resistant ceramic tiles can be cut into any shape and are easy to install and maintain. They are suitable for both wet and dry processing applications. Advanced ceramics combine high strength and toughness with extreme hardness to deliver exceptional wear resistance.Ceramic wear-resistant tiles are pressed with chamfered sides and cut precisely to the required shape, ensuring that gaps between the ceramic wear-resistant tiles are minimised and tile wear is reduced as chipping is eliminated.Benefits of Ceramic Wear-Resistant Tiles:· Zero friction against minerals· The highest protection against abrasion and corrosion· Wear protection up to 400°C· Longer life than traditional wear protection· Reduce downtime and maximise your plant’s productivityCeramic: 92% & 95% Alumina, RBSiC, ZTAAvailable with square, rectangular, cylindrical or hexagonal,etc.Cushion Rubber/ PU: Superior rubber/PU compound, impact-absorbingConnection: Steel plate and studs / cn bonding layer, both available to suit different types of applicationsThe thickness of complete liner, ceramic and rubber/PU are determined on the basis of application, such as handled material lump size, height of fall, impact angle, etc.

Ceramic/rubber lining material is a composite construction of highly wear-resistant 92 %-Al2O3 ceramic tiles (square, rectangular or hexagonal „SW“) vulcanized in special rubber with CN bonding layer. Properties • CN bonding layer provides fast andlonglasting adhesion• Highest abrasion resistance• Reduces operating costs• Long service life increases the efficiencyof your equipment• Good resistance against weather Area of application • Lining against extreme wear throughabrasion at high speeds• For simple to medium duty applicationsin mining, gravel, sand and stone breakingmills and other industrial sectors• In applications like pipelines, vibratoryfeeders, cyclones, skips, bunkers, chutes,loading points, slides, hoppers, silos

Abrasion is always unavoidable in the processing and transport of bulk materials. The falling material flow causes particularly strong impact. We offer our customers best solutions with the high-quality ceramic wear matrix(with/without steel plate and bolt), in order to achieve an optimal result in increasing the impact resistance and reducing the abrasion and noise. Features:* Extremely high impact resistance* Low friction coefficients*Noise reduction* easy and fast montageApplications:*Lining of funnels and containers*Slides and transfer stations*Pipeline case*Vibration chutes and chute boxes*Application at the transfer pointsType of Ceramics : * Cylinder *Hex Tile* Rectangular* Square*Cube 92%, 95%, 99% Al2O3, ZTA, Zirconium, RBSIC Silicon Carbide Dimension of the Liners: Regular&Customized,Max L800*W800mm

Cold Bonded Wear PanelsQMX Wear Panel solutions are ideal for a wide variety of mining, mineral processing and material handling for protection against extreme wear.ApplicationTypical application examples:· Chutes· Cyclones· Launders· Pipes and tanks· Conveyor transfer points· Screen beams, underpans and components· Vibratory feedersKey features and benefits· 92% Aluminium oxide material.· Rubber compound blended with CN polymers.· Buffed CN bonding layer and buffed edges.· Manageable size and weight. Strip width 250mm makes it easy to install.· Fire resistant and antistatic (FRAS) rubber compound available.· Low sulphur rubber.· Ceramic tiles bonded to rubber on all sides (except top surface).· Supplied in square panels 500mm x 500mm.· Extreme wear resistance.· Outstanding adhesion to ceramic tiles, rubber and metal.· For optimum cold vulcanised adhesion.· Can be used in above and below ground applications.· Stable rubber hardness with age.· Resists tile cracking and pull out.· Easy to install.Rubber,Ceramic&Steel SpecificationS.No.MaterialAttributesProperties1Ceramic TilesMaterial92%, 95%, T95%,99%, ZTA2RubberComponentNatural rubber, nitrile-butadiene rubber ,Flame Retardant ,othersDensity~1.4g/cm3Tensile strength at break≥10.6MpaElongation at break ≥350%Shore Hardness45-65Adhesive between tile and rubber≥3.8 MpaAdhesive between rubber and equipment≥3.58MpaThermal conductivity.(normal temperature)2w/m·kAging period≥15 YearsWorking temperature-50ºC - 200ºC3Steel plateMaterialQ235ADensity7.85g/cm3Thickness3-10mm4AdhesiveAppearanceBrown glutinous liquidSolid content 20±3%Viscosity≥2.5 MpaPeel strength 48h N/2.5cm≥120Compressive strength≥850 MpaWorking temperature-20ºC - 100ºC

Chute ceramic wear liner tileThe ceramic wear liner backed steel plates are hot vulcanized together with the high tensile strength 7mm nature rubber sheet and 6mm steel backing plate. As a result the ceramics wear liner will have both advantages of the rubber impact resistance and ceramic wear resistance. Size of Rubber backed Alumina wear plates 1NO.sizeceramic+rubber+steelNote1500*500*5028+16+6Hex Tile L23.1xT282300*300*6350+7+6147*97*503300*300*3525+4+6147*97*254298*298*6350+7+6147*97*505190*390*2515+4+6Hex Tile L12.5xT156500*500*2013+1+620*20*137450*400*6350+7+6147*97*508400*300*6350+7+6147*97*509450*300*6350+7+6147*97*5010300*200*3725+6+6147*97*5011300*200*3725+6+6147*97*5012300*150*6350+7+6147*97*5013500*500*5030+14+647.5*47.5*3014500*500*3220+6+647.5*47.5*3015500*250*3220+6+647.5*47.5*3016500*500*2820+2+6φ20*2017500*500*5040+4+6φ40*4018300*300*3320+7+6φ20*2019390*190*6340+17+6φ40*4020302*302*3220+6+6φ20*2021500*500*3220+6+6φ20*20Customized Sizes can be manufactured.FeatureModular Bolt-In SectionsNot Limited to Standard Sizes and ThicknessesHighly CustomizableFast Installation & ReplacementCost EffectiveImpact AbsorbingAbrasion ResistantNoise ReductionLighter Compared to Steel

Superior wear resistance of high alumina ceramics.Energy-absorbing rubber cushions, more impact resistant.Extend wear life of your production line, reduce maintenance and downtime.Alumina ceramic lining is a high abrasion-resistant wear product, it is a combination of high alumina ceramic tiles and natural rubber.High alumina ceramic lining offers wear protection and can extend service life of chute or other equipment significantly, wear life of high alumina ceramic is approx. 5 timers longer than rubber and 10 times longer than steel. Installation for ceramic lining1. Rubber ceramic lining produced with steel plate and stud-fixed to steel plate by studs, nuts and washers.2. Ceramic lining with cn bonding layer.-be bonded to steel plate by adhesive.3. Alumina ceramic lining can also be produced with steel or aluminum channel-fixed by studs

alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Wear-resistant hex mats prevent erosion and abrasive wear in conveying and bulk material handling systems. Their flexible design allows for lining of intricate systems including fan blades, chutes, hoppers, and more.Order quantities may range from one box of ten mats up to container loads. Mat Size RangeThickness Range: 1/8” through 1” (Metric: 3-25mm)Size Range: 6” x 6”, 12” x 12” 12”x20” (Metric: 150x150mm, 300x300mm, 300x500,mm)Technical SpecificationsCeramic Material: 92%, 95% Alumina Surface Finish: As-FiredDimensional Tolerance: ±1%L*WHNote10*103--10mmBulk pieces or Mats17.5*17.53--15mmBulk pieces or Mats20*204--15mmBulk pieces or Mats25*254--10mmBulk pieces or Mats12*126--25mmBulk pieces or Mats12.5*12.56--25mmBulk pieces or Mats

High Alumina Ceramic Tiles Mats Product Description:Alumina Ceramic square tile mats is combination of high hardness alumina mosaic tile and backed silk , paper or net .the low friction , smooth surface prevents materials build-up in low inclination installations. The square ceramic tiles make it possible to bend the sheeting which makes it perfect protection for con-ave and convex surface .the sizes of ceramic square tile matted can be easily be adjusted by bending the sheeting and cutting it in between the ceramic tiles .this alumina ceramic square tile matted has advantages including : no specialist tools required, can be applied to most substrates . Convenient design for fast and easy application .Alumina ceramic tile mats advantages :> High hardness with Moh’s hardness 9 grade> High abrasion and chemical resistance> Easy installation by epoxy resin glue water> Easy mending if someone hex tile drop off> Various of alumina ceramic hex sheet size availableSizes:L*WThk.Ceramic mats(stick on Sticker/nylon Mesh/Acetate/Paper10*103--10mm150*150mm17.5*17.53--15mm150*150mm, 300*300mm,300*500mm20*204--15mm300*500mm25*254--10mm/12*126--25mm/12.5*12.56--25mm/

Product Name:Alumina Ceramic Hexagonal TilesProduct H.S Code:690912Product Materials:AluminaProduct Color:WhiteCertificate:ISO9001Customized:AvailableProduct Packaging:Cartons and Pallet Product Details:QMX alumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel Size of Alumina Mosaic Ceramic ( square / Hex.) TilesL*WHNote10*103--10mmBulk pieces or Mats17.5*17.53--15mmBulk pieces or Mats20*204--15mmBulk pieces or Mats25*254--10mmBulk pieces or Mats12*126--25mmBulk pieces or Mats12.5*12.56--25mmBulk pieces or Mats

QMX Ceramic Tile is a preferred liner option in areas of extreme small particulate abrasion with minimal impact. The 90% fine grain, high grade alumina is manufactured to the highest standards, producing a premium product that can hold up to your most abrasive materials. Ceramic tiles offer great mechanical properties with superior sliding abrasion resistance.QMX Ceramic Tiles are offered in several thicknesses to address the requirements of your specific application. QMX Tiles are offered with a choice of attachment methods for optimal performance.ADVANTAGES· Greatest Level of Sliding Abrasion Resistance· Cost Effective· Multiple Thickness Options· Chemical Resistance Attachment Options: Epoxy or Weld-in STANDARD THICKNESSESThickness1/4″=6mm1/2″=12mm3/4″=20mm1″ =25mm2″ = 50mm

Ceramic tiles have excellent abrasion and wear resistant qualities and are ideal for use in transfer chutes, piping systems, hoppers, etc. Typical markets include grain, coal-fired power generation, mining, cement, and more.QMX Manufactures a full range of high-density, fine-grain, wear-resistant alumina ceramic wear tiles to prevent erosion and abrasion in conveying and bulk material handling systems. Our alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Weldable tiles are provided with a hole though the tile, a carbon steel weld cup, and a ceramic plug for welding in pace onto a steel substrate.LengthWidtThickness50501550501750502060203560401070701070701575752075752575753075753510050810050121005012.510050151005020100502510075121007520100752510075301001001010010012100100151001002010010025100100301001003510010040100100451208081208010120801212080141208015120802012080251208030150501015050121505012.71505015150502015050251505030150503515050401505050150100101501001215010014150100151501002015010023.5150100241501002515010030150100401501005015010070

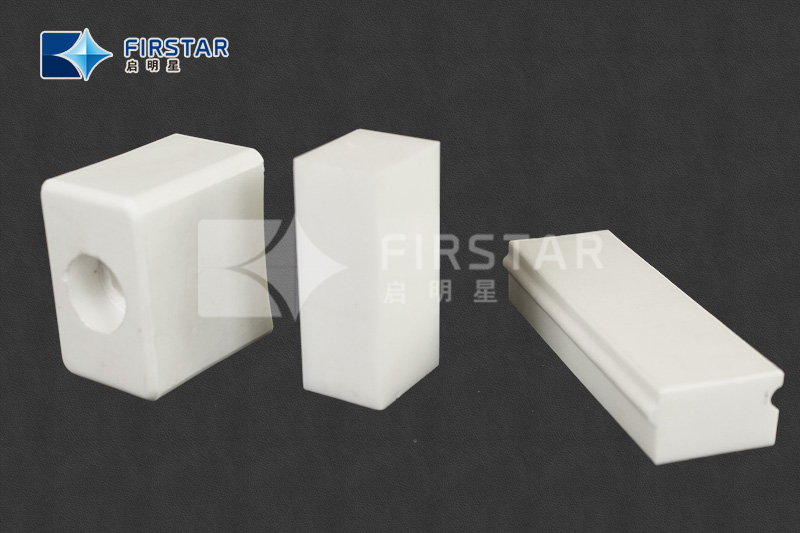

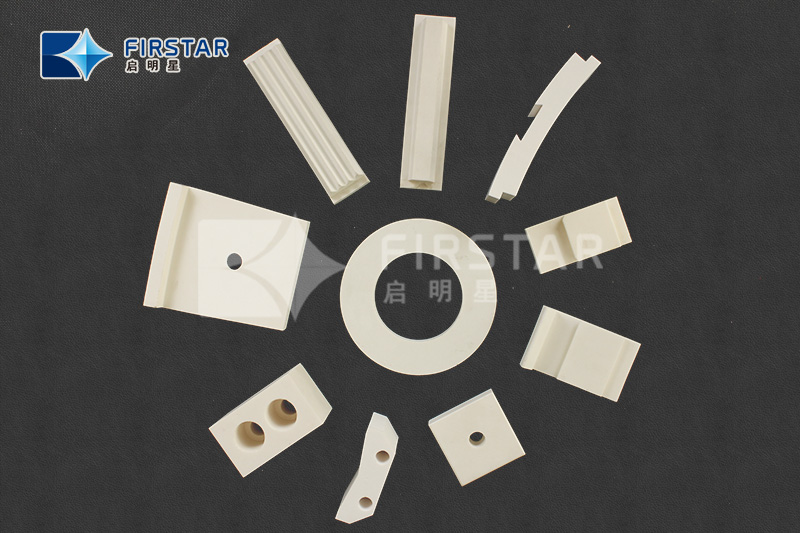

Engineering alumina ceramic liner is different standard ceramic tile , designed and tailor-made with CAD Software to suit any type of customer’s components . QMX ceramics offer a range of wear resistant ceramics products that have been engineered to meet the equipment abrasive requirement of special angle , shape,radian,sizes etc.which can be perfectly installed without gaps and fitted for equipment. QMX has experienced to design engineering alumina tiler chute liner like hopper liner , cyclone liner etc. Also will help with your wear problems well .Products Characters :-- Long lifetime and maintenance free operation -- No operation interruption or production losses -- Maximum efficiency of separation --Perfectly fit for equipment without cutting Application industry > mining industry > Cement industry > Coal handling industry > Steel industry > Port industry > Power plant Technical data :Chemical Composition:Al2O3SiO2CaOMgONa2O92~93%3~6%1~1.6%0.2~0.8%0.1%Physical Properties:Specific gravity (g/cc)>3.60>3.65>3.70Apparent porosity (%)000Bending Strength (20℃, Mpa)220250300Compressive strength (20℃, Mpa)105013001600Rockwell hardness (HRA)828588Vickers hardness (HV20)105011501200Moh’s hardness (scale)≥9≥9≥9Thermal Expansion (20-800℃, x10-6/℃)888Abrasion Loss (Cm3)0.250.20.15

Silicon carbide CycloneReaction bonded silicon carbide is a multi-phased material typically containing 7-15% silicon metal, some minor amount of unreacted carbon, with the remaining body being SiC. Reaction bonded SiC materials are manufactured utilizing a variety of processes depending on desired final product geometry, configuration, and required tolerances.Reaction bonded silicon carbide has proven to be an excellent material choice for wear applications such as pipe liners, flow control chokes and larger wear components in the mining as well as other industries. CALSIC RB offers an economical and reliable material option for many applications where the corrosion resistance or wear resistance of CALSIC S (sintered silicon carbide) is not necessary.Typical properties of silicon carbide are:Excellent thermal shock resistanceExcellent hot strengthExcellent abrasion resistanceGood thermal conductivityRelatively low coefficient of thermal expansionTypical applications for silicon carbide are:Kiln furniture for powder metal and ceramic processingKiln components including:hearthsentrance tilesskid railsmufflesside wallsarchesReaction Bonded Silicon Carbide PropertiesPhysical PropertyUnitsTypical ValueMicrostructure%87% SiC, 12% SiDensityg/cc> 3.02Apparent Porosity%< 0.1Max Use Temperature°C1380Flexural StrengthMPa250 @ 20°C280 @ 1200°CCompressive StrengthMPa2500Modulus of ElasticityGPa330 @ 20°C300 @ 1200°CCoefficient of Thermal Expansion1 x 10-6 in/in °C4.5Thermal Conductivity @ 1200°CW/mK45Poisson's Ratio-0.2Vickers HardnessGPa20-22

Silicon carbide wear lining tiles/blockInner Lining and Blocks for Industry MaintenanceSiSiC: Moh’s hardness is 9.5 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Wear resistant ceramic lining is conductive to make improvement of the production performance, the working efficiency, the reduction of maintenance costs and the increase profits.- Excellent wear and abrasion protection property.- Excellent corrosion resistance property- Excellent heat resistance property- Excellent impact resistance property- Excellent for ballistic protectionApplications:- Mining- Mineral processing (mineral beneficiation)- Power generation- Cement- Petro-Chemical Refining and Production- Coal washery- Steel- Defense (personal & vehicle armour).■ Specifications: Item Unit Data Temperature of application ℃1380℃ Density G/cm3 >3.05Open porosity % <0.1 Bending strength -A Mpa 250 (20℃) Bending strength -B MPa 280 (1200℃ ) Modulus of elasticity-A GPa 330(20℃) Modulus of elasticity -B GPa300 ( 1200℃ ) Thermal conductivity W/m.k 45 (1200℃ ) Coefficient of thermal expansionK-1 ×10-64.5 Rigidity /13 Acid-proof alkaline / excellent■ Available Shape and sizes:Thickness: from 6mm up to 25mm Regular Shape: SiSiC tiles, SiSiC Pipe tiles, SiSiC Three Links, SiSiC Elbow, SiSiC Cone Cyclone. Remark: Other sizes and shape are available upon requests. ■ Packaging: In carton box, packed in fumigated wooden pallet with net weight 20-24MT/20′FCL.

Wear resistant ceramic which are mainly composed of at least 90% Al2O3 are the most widely used in the world today.Our products are made from strictly selected alumina powder with uniform particle sizes and low CaO content.Wear resistant ceramics can be made through common dry press or isostatic pressing process and then sintering them at high temperature in the kiln. They are desirable lining materials for high wear equipment due to precise dimensions, high density,high alumina content,good flatness and stable quality.CategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3Notes: We can make alumina wear tile according to your requirement.FeaturesHigh hardnessRockwell hardness of high alumina ceramics is up to HRA80-90 which is second only to diamond and far exceeds wear-resistant steel stainlessExcellent wear resistanceThe wear resistance of high alumina ceramics is 266 times that of manganese steel and 171.5 times that of high chromium cast iron.According to our investigation & follow-up to the clients, the service life of equipment can be prolonged over 10 times under the same working conditions.Corrosion resistanceHigh alumina ceramics are inorganic oxides with extremely stable molecular structure and no electrochemical corrosion, thus they can resist erosion of acid, alkali, salt solutions and organic Solvents.ThermostabilityWorking temperature of high alumina ceramics can be as high as 1400℃.Good self-lubricityHigh alumina ceramics have the properties of self-lubricity and inadhesion, the roughness is only 1/6 that of steel pipes thus less flow Resistance.Light weightThe density of high alumina ceramics is about 3.6g/cm3, which is only half that of steel, thus easy for construction and installationWear solutions we provideThis is a complex process.Our engineers understand wear problems and specifysolutions to meet your operational environment. Material properties,tolerances, flatness,attachment methods, and material costs are all considered in a wear solution.Applications• Chutes/Hoppers• Classifier Cones• Cyclone Separators• Elbows• Fan Housing & Blades• Lined Piping• Nozzles• Wear PanelsMarkets• Coal-fired Power Generation• Abrasive Material Handling• Chemical Processing• Food Processing• Iron/Steel Manufacturing• Mineral Processing• Powder/Bulk Solids Conveying• Pulp & Paper Manufacturing• Pulverizing & Grinding

Ceramic cyclone parts alumina spigot apexThe material cyclone suffered serious abrasion and impact when it separated the material particle, like coal, gold, iron and ext. because of high speed material conveying. It’s very easy to wear out to leak the material from cyclone and a suitable wear protection solution for material cyclone is very necessary.ULTRAMING used the ceramic liners lined into the inner wall of the cyclone to get the wear & impact protections. It has been turned out it’s a very good wear solution for material cyclones.Also, we can design different shape and thickness ceramic liners for the cyclones according to different working conditions. Custom cyclone can be made according to client’s drawing.Applications:1.Coal2.Mining3.Cement4.Chemical5.Steel

1. ApplicationAlumina ceramic cylinder bushing liner / lining tube / sleeve lining with high abrasion resistance are widely used for serious abrasive environments, such as chute liners, cyclone liners, conveyor skirt liners, processing piping liners, hopper or silo liners, screen equipment liners in the industries including ,but not limited to: ♦ Coal Preparation Plants ♦ Coal Fired Power Stations♦ Mineral Processing Plants ♦ Cement Plants♦ Chemical Plants ♦ Steel & Iron Plants♦ Railway Stations ♦ Ports 2. PropertiesHigh density, high hardness, low wear loss, regular shape, impact resistance, corrosion resistance, etc. 3. Standard DimensionOD12MM, ID10.2MM, THICKNESS: 8MM, H4.5MMdifferent sizes for your selectionProductIDODThicknessLengthRDegreeStraight Tube7610615150-250//Straight Tube10014020305//Straight Tube15018517.5150-250//Straight Tube15218215150-250//Straight Tube20024020305//

Wear resistant pre-engineering tile in a variety of geometric shapes from simple to complex,the ceramics can be engineered or mould to specific shapes to customer's requirement.Ceramic lined equipment like pipes,bends,chutes,hoppers,bunkers, etc. Alumina ceramic liner has excellent abrasion resistance,hard resistant,corrosion resistance,it is widely used in the mining,power plant,steel plant,cement industries like chutes, hopper,bunker,cyclone,convey belt, etc. This alumina ceramic product make cost effective performance like reduce un-necessary down time and maintance,and prolong the equipment from quick abrasion.Engineered linings product is a speciality We can supply and install a wide range of pre-engineered alumina ceramic tiles tailor-made to suit any type of application . CAD software is used to design wear resistant lining for customer's components. Machining before sintering makes us able to provide linings with complex and 3 dimensional shapes as a cost-effective solution. Which will fit nearly any geometry , A well designed engineered lining system different from standard ceramic tile bricks will make equipment with special angle without gap, so it avoid materials wastage and machines wear damage . Feature· Excellent corrosion resistance property· Easily handled size and weight· Excellent heat resistance property· Excellent impact resistance property· Fast and safe installation· Lower production and maintenance costAlumina Ceramic Advantages· Professional technical team to afford CAD designs· Professional installation team to afford install service· Well established process as per international standards· Accept the standard and pre-engineered tiles QMX type of ceramic tiles-Alumina plain Tile-Pipe tile-Radius tile-Curved tile-Weldable/weld-on tile- engineered tile

Customized Ceramic Wear TilesQMX offers a full range of shapes and sized ceramic tiles for your severe wear lining applications. QMX can offer standard sized tiles (square and rectangular), hex tiles as well as custom shapes and sizes for your demanding application.QMX offers a complete material portfolio for these ceramic wear tiles including; several grades of Aluminum Oxide 92%, 95%, 99%, Zirconia Toughened Alumina(ZTA), Zirconia, Reaction Bonded Silicon Carbide as well as Sintered Silicon Carbide for your most extreme corrosion, abrasive and wear environments.Please contact us and allow our application engineers the opportunity to work with your engineering team to recommend the right advanced ceramic materials for your toughest challenges.

QMX wear and abrasion resistant linings reduce downtime and maintenance and are marketed throughout the world. These wear resistant linings serve a variety of processing equipment including hydraulic and pneumatic components and pipes handling large quantities of bulk materials. We offer wear solutions for iron and steel, mining, power, cement and other industries. We are your source for total custom piping solutions too! Complete planning, design, pricing, fabrication and installation. We know pipe!

Alumina Lining Brick(1) ApplicationWidely used in power plants, steel mills, chemical, rubber, and coating fields, is the ideal surface wear-resisting material for material transfer equipment in mining, iron & steel works, thermal &powder plants, mine, etc, also used in ceramic, glaze, paint, zirconia silicate, alumina oxide, quartz, silicon carbide, lime carbonate, and mechanical equipment accessories, can extend the operating life effectively.Theoretically the life time of the alumina ceramic is about 260 times longer than that of manganese steel and 170 times longer than that of chrome steel.(2) PropertiesHigh density, high hardness, low wear loss, regular shape, impact resistance, corrosion resistance, etc.(3)Chemical PropertyCategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3(4) Standard Dimension150x100xH40-90MM(5)PackageDifferent package as to meet different customer’s requirements.Wooden Crates carton Plastic Pallet(6)Application:Ceramic complex pipeline of glass fiber reinforced plastics,Alumina ceramic liner for cement cyclone,Metal complex pipeline and elbow,Abrasive liner for down spouting,Abrasive liner for pipeline,Preheater bracket,Abrasive wheel of powder.

Wear-resistant elements prevent destruction in the transportation, processing, mining and other technological equipment. The elements are made of high-purity, finely dispersed, alpha-alumina. Wear-resistant plates can be made from a variety pre-designed element of different dimensions and forms. 1. Standard tiles(alumina plain tiles)Standard ceramic tiles are used for protection against wear, especially on the flat and straight-line surfaces. Special sizes are on the Customer's request. 2. Weld-on Tile Welding tiles have a hole, and complete with carbon steel riveting and a ceramic plug for welding 3. Ceramic Mosaic Ceramic mosaic is widely used as a lining (facing) tile in the conveyor equipment to protect the drive pulleys of belt conveyors from wear, increases the tape engagement ratio, excluding its slippage. 4. Mosaic matsThe mosaic mats consist of small mosaic tiles glued to acetate silk or PVC mounting film. Standard mats are 250x250 and 500x500 mm. Standard thickness is 3-12 mm. The mats consist of a square tile of 10x10 or 20x20 mm, or a hexagonal tile of SW20/40 mm. Special sizes are on the Customer's request. 5. Ceramic tubesCylinders and spherical segments provide solid protection for steel pipes from abrasive and corrosion wear, even with a small wall thickness. Standard dimensions of inner diameter are 40-500 mm. Special sizes are on the Customer's request. 6. ZTA ceramics The combination of aluminum oxide and zirconium dioxide (ZTA) increases strength, toughness, hardness and wear resistance in 20-30% in comparison with pure alumina ceramics. The maximum temperature for application of products from ZTA ceramics is 1450 ° C. 7. Customized elementsIt is possible to design and manufacture a comprehensive wear-resistant protection and to adapt protective schemes for the Customer's tasks. Special processing of products prior to sintering allows to manufacture products of complex three-dimensional shape.

QMX manufactures a full range of high-density, fine-grain, wear-resistant alumina ceramic hex mats (hexagonal tiles). Our alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Wear-resistant hex mats prevent erosion and abrasive wear in conveying and bulk material handling systems. Their flexible design allows for lining of intricate systems including fan blades, chutes, hoppers, and more.Order quantities may range from one box of ten mats up to container loads. Size RangeThickness Range: 3-25.4mmSize Range: 150x150, 250x250, 300x500, 500x500 mmTechnical SpecificationsCeramic Material: 92%, 95%,99%, ZTASurface Finish: White Dimensional Tolerance: ±1%Maximum Temperature Limit: 1,500° C

Ceramic mosaic is widely used as a lining (facing) tile in the conveyor equipment to protect the drive pulleys of belt conveyors from wear, increases the tape engagement ratio, excluding its slippage. The mosaic mats consist of small mosaic tiles glued to acetate silk or PVC mounting film. Standard mats are 150x150, 300x500 and 500x500 mm. Standard thickness is 3-12 mm. The mats consist of a square tile of 10x10 or 20x20 mm, or a hexagonal tile of SW20 mm. Special sizes are on the Customer's request. Alumina content: 92%, 95% and 99%Packing: 25kg pp bag on pallet

The rubber-ceramic lining of pulley is particularly suitable in cases where slippage and excessive wear make normal rubber lining ineffective. Alumina ceramics tiles allow to maintain the correct position of the belt, even in conditions of high humidity, heavy pollution and abrasive impact. Also, by varying the thickness of the ceramic elements and the total thickness of the lining, it is possible to compensate the difference in diameters of the pulleys A. Rubber:1. Material: NR&BR2. Density: 1.15 g/sm3. Tensile strength: 24 MPa4. Shore hardness: 60±55. Elongation: 360%6. Wear lost: 85 mm37. Ageing coefficient: 0.87 (70C°x48 hours) B. Alumina ceramics:1. Material: Al2O3 92-95%2. Density: 3.6 g/cm3 3. Colour: wight4. Wear lost:<0.20cm35. Hardness: Mohs 9

QMX supply and install a wide range of Alumina Wear Resistant Tiles for wear protection of all areas such as Chutes, Silos, Feeders, Bins, Launders, Dutching, Tanks, Bunkers, Hoppers, Underpans etc.Described as the material of the future, alumina ceramics is one of the hardest of all natural substances known to man. Under extremely abrasive conditions, no material can compete on a cost to life basis with it's extreme hardness and wear resistance. In addition, alumina ceramics has exceptional chemical, mechanical, thermal and electrical insulation properties and can be formed into any shape or size with various qualities for specific applications. Weld-On alumina ceramic tiles are typically used in high temperature applications and are available in most sizes to suit your application on an ex-stock basis.CategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3

PU grinding mediaPolyurethane ball is zero pollution medium ball which purchased by part of the specific high-tech enterprise. Our company adopts the special processing technology to ensure the concentricity of the inner metal ball and outer polyurethane lining, greatly improved its service life, and safety character. Now it is widely used in the grinding and mixing of all kinds high grade materials.Our company can make various kinds of ceramic grinding media professional, is a high and new technology enterprise, has passed ISO9001 quality system certificate, can make high wear resistance and high strength aluminum zirconium silicate composite beads, and other production process, we has a patent for invention, production,received extensive recognition and application at home and abroad.Our product, include all kinds of grinding media(zirconia bead, alumina bead, zirconia silicate bead, ZTA bead) is mainly used in coating, paint, printing ink, ceramics, ink, electronic ceramics, titanium dioxide, pesticides, Kaolin, calcium carbonate, special chemical and other industries, zirconia bead, mainly used in Nano materials(such as lithium battery, barium sulfate, grinding ceramic ink, etc.)Specific Density 11.3kg/LTear Strength40-100KN/mShore A Hardness35-95Tensile Strength30-50MPaAkron abrasion<0.053(CM3/1.61km)Deformation<8%Working Temperature-25-80℃Insulation StrengthExcellentExpansion strength70KN/mGrease resistantExcellent