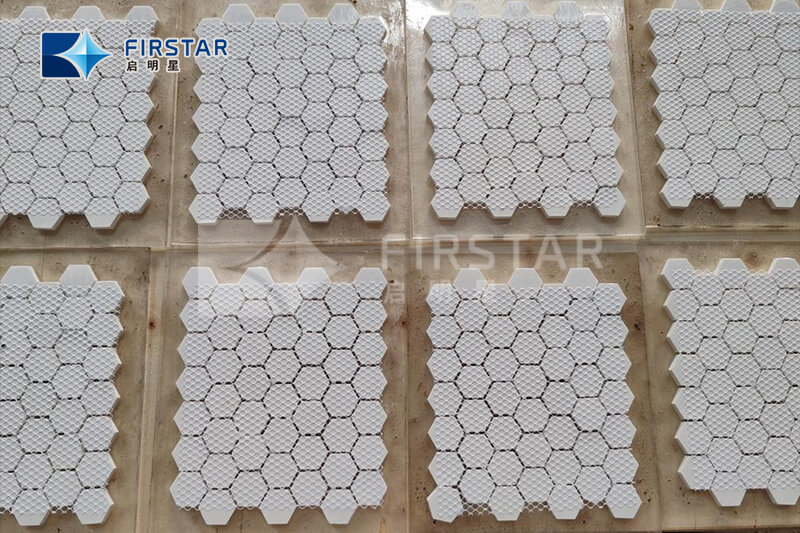

Hex Ceramic Tile Lining Kit

Abrasion resistant lining

Our Alumina abrasion resistant ceramic linings are highly durable and have a significantly longer lifespan compared to lower grade materials typically used for lining or protecting processing and material handling equipment. These linings can outlast these lower grade materials by factors ranging from 3 to 15 times.

One common application for our Alumina ceramic linings is in grain transitions. These transitions are areas where grains are moved from one section to another, and they are prone to wear and tear due to the abrasive nature of the grains. By using our ceramic linings, these transitions can be protected and their lifespan can be extended.

Similarly, grain spouts, grain elbows, and grain chutes are also susceptible to abrasion and deterioration. Our Alumina ceramic linings provide excellent resistance against wear, allowing these components to withstand the constant flow of grains without experiencing significant damage. This greatly reduces the need for frequent replacements and maintenance.

Grain conveyors, hopper bins, and grain valves are other critical equipment in the grain handling industry that can benefit from our ceramic linings. These components are exposed to high levels of abrasion and impact as grains are transported and processed. By installing our Alumina ceramic linings, these equipment can be protected from wear and damage, resulting in improved reliability and reduced downtime.

Overall, our Alumina abrasion resistant ceramic linings offer superior longevity compared to lower grade materials commonly used in the industry. By choosing our ceramic linings, businesses can significantly reduce maintenance costs, minimize equipment downtime, and extend the operational lifespan of their processing and material handling equipment.

Technical Specifications

Ceramic Material: High Alumina Fine-grain Alumina

Surface Finish: As-Fired

Dimensional Tolerance: ± 1~1.5%

Dimension Available: 150x150mm | 300x300mm |300*500mm|500*500mm

| Category | HC92 | HC95 | HCT95 | HC99 |

| Al2O3 | ≥92% | ≥95% | ≥95% | ≥99% |

| ZrO2 | / | / | / | / |

| Density (gr/cm3) | >3.60 | >3.65g | >3.70 | >3.83 |

| HV 20 | ≥950 | ≥1000 | ≥1100 | ≥1200 |

| Rock Hardness HRA | ≥82 | ≥85 | ≥88 | ≥90 |

| Bending Strength MPa | ≥220 | ≥250 | ≥300 | ≥330 |

| Compression strength MPa | ≥1050 | ≥1300 | ≥1600 | ≥1800 |

| Fracture Toughness (KIc MPam 1/2) | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 |

| Wear Volume (cm3) | ≤0.25 | ≤0.20 | ≤0.15 | ≤0.10 |

Alumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market.

Alumina Ceramic Tile is of high wear resistance, acid and alkali resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel.

Advantages:

1. High hardness, its Rockwell hardness is HRA80-90, the hardness is second only to diamond

2. Long service life, under the same working conditions, the service life of the equipment can be extended by more than 10 times.

3 Light weight, its density is 3.6g/cm3, which can greatly reduce equipment load.

4. The bonding is firm and the heat resistance is good. The hexagonal ceramic tile mat is pasted on the inner wall of the equipment with heat-resistant super glue.

Application:

Widely used in anti-wear material conveying systems in coal, thermal power, steel, cement, mining, port, chemical and other industries, such as coal washing plants, thermal power plants, coal pipes, coal hoppers; coke hoppers in steel plants; mining transfer hoppers; cement plant clinker, cement chute, hopper.