and Wear Resistant Products

THE IDEAL SOLUTION FOR COMPLICATED WEAR PROTECTION APPLICATIONSSilicon carbide ceramic is distinguished from other wear protection materials in particular by its very high resistance to temperature fluctuations. Therefore, it is used both as protection against abrasive wear and shock wear at extremely high operating temperatures and at the same time strong and rapidly successive temperature changes.MANUFACTURE AND PROPERTIESAccording to the material classification for ceramic materials, silicon carbide ceramic belongs to the group of ceramic materials composed of non-oxides.There are two types available:• The starting point is high-quality raw materials of silicon carbide, silicon dioxide (SiO 2 ) and aluminium oxide• Special quality due to a bond of silicon nitride (Si 3 N 4 )SiC granules are mixed with temporary and permanent binders. Production takes place in a dry, semi-dry or compression process. Moulded parts are produced after the casting process, followed by a sintering process.Features:• Excellent resistance to temperature fluctuations• High temperature resistance• High hardness• High thermal conductivity• Resistance to corrosion• Max. operating temperature up to 1400°C, depending on qualityKey Material PropertiesITEM:UNIT:DATA:TemperatureCelsius1380 cDensityg/cm³3.1 – 3.2Open porosity%≤1.56 – 1.66Bending strengthMPa250 ( 20 c )MPa280 ( 1200 c )Modulus of elasticityGPa330 ( 20 c )GPa300 ( 1200 c )Thermal conductivityW/m.k45 ( 1200 c )Coefficient of thermal expansionK-1 x 10-64.5Rigidity13Acid proof alkalineExcellentStandard ToleranceFlatness≤ 0.2%Thickness+ / – 1.0 mmLength / Width+ / – 1.5 mmKey ApplicationsReaction Bonded Silicon Carbide for Kiln Furniture and Support Components– The high temperature strength, oxidation resistance and thermal shock resistance of Reaction Bonded SiC enables the manufacturer of low mass kiln supports. Kiln products include thin walled beams, posts, setters, burner nozzles and rolls. The components lower the thermal mass of kiln cars, result in energy savings and provide the possibility for faster product throughput.Reaction Bonded Silicon Carbide for Wear Parts and Thrust Bearings– Wear resistance, high temperature strength and corrosion resistance make Reaction Bonded SiC an ideal material for wear components, such as screws, plates and impellers. It can also be used in thrust bearings that can carry extremely high loads in heavily contaminated liquids.Reaction Bonded Silicon Carbide for Mechanical Seals and Vanes– Reaction Bonded SiC can be used in mechanical seals and pump vanes with high abrasion resistance.Reaction Bonded Silicon Carbide for Precision Components– The negligible volume change after reacting with liquid silicon means that components can be formed with complex shapes and to exacting tolerances. The components are lightweight and stiff with excellent thermal stability.Silicon Carbide Wear Ceramics,Zirconia Toughened Alumina (ZTA),High-Temperature Wear-Resistant Solutions,Industrial Ceramic Lining for Mining,Refractory Ceramic MaterialsZibo Qimingxing's Silicon Carbide Wear Ceramics: Engineered for Extreme Environments. With 1300+ HV hardness, 1400°C heat resistance, and corrosion-proof design, our RBSiC/SiSiC solutions deliver unmatched durability for mining, cement, and chemical industries. Contact us for customized wear protection.

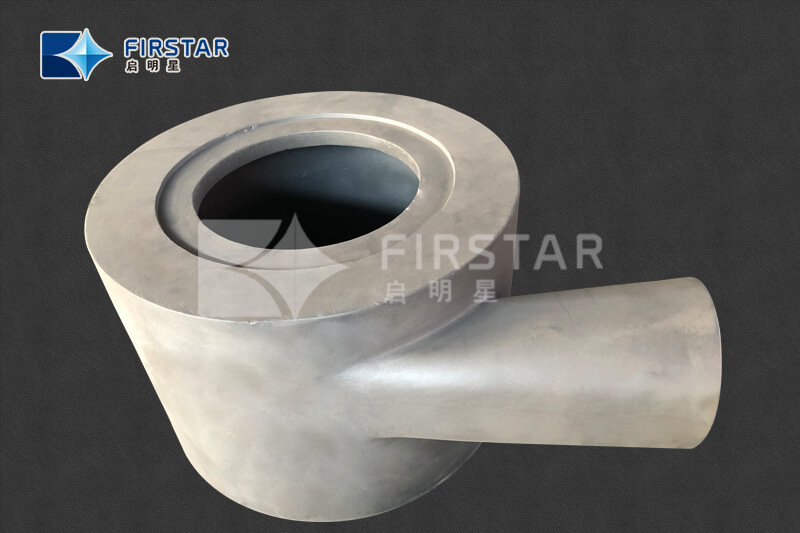

Polyurethane Encased Hydrocyclone Liners QMX’s turn-key solution for hydrocyclone slurry separators and other mineral processing equipment delivers single-sourced, completed encapsulated assemblies in just weeks. Where required, our proprietary silicon carbide based formulations can be cast into complex shapes and then encased in polyurethane in-house, providing ease of installation, crack mitigation and added wear insurance, all while delivering a complete solution from one vendor. The VERKAPSE process reduces both cost and lead time for customers while providing a product with greater overall durability and reliability.All proprietary silicon carbide based materials can be cast into very complex shapes, displaying tight and repeatable tolerances that ensure repeated ease of installation. Expect a more abrasion resistant product than cast steels, rubber and urethanes alone at one-third the weight of their steel counterparts. All offer much higher thermal and corrosion resistance. QMX also produces monolithic drop-in replaceable silicon carbide cyclone and hydrocyclone liners specifically engineered for separating and classifying applications. These ceramic liners are designed for highly abrasive ores including coal, iron, gold, copper, cement, phosphate mining, pulp & paper and wet FGD and are available in sizes up to 60″ in diameter.A variety of highly abrasion resistant ceramic compositions are available, maximizing cyclone life and eliminating high installation costs traditionally found in epoxied tile constructions. This assists both OEMs and single plants in achieving financial performance objectives by optimizing classification efficiencies.QMX supplies either the complete assembly of the hydrocylone or the high wear areas including the bottom apex and spigots. Cones, cylinders, vortex finders and volute feed inlet heads are precision cast for repeatable assembly into your existing hydrocyclone.

Silicon carbide CycloneReaction bonded silicon carbide is a multi-phased material typically containing 7-15% silicon metal, some minor amount of unreacted carbon, with the remaining body being SiC. Reaction bonded SiC materials are manufactured utilizing a variety of processes depending on desired final product geometry, configuration, and required tolerances.Reaction bonded silicon carbide has proven to be an excellent material choice for wear applications such as pipe liners, flow control chokes and larger wear components in the mining as well as other industries. CALSIC RB offers an economical and reliable material option for many applications where the corrosion resistance or wear resistance of CALSIC S (sintered silicon carbide) is not necessary.Typical properties of silicon carbide are:Excellent thermal shock resistanceExcellent hot strengthExcellent abrasion resistanceGood thermal conductivityRelatively low coefficient of thermal expansionTypical applications for silicon carbide are:Kiln furniture for powder metal and ceramic processingKiln components including:hearthsentrance tilesskid railsmufflesside wallsarchesReaction Bonded Silicon Carbide PropertiesPhysical PropertyUnitsTypical ValueMicrostructure%87% SiC, 12% SiDensityg/cc> 3.02Apparent Porosity%< 0.1Max Use Temperature°C1380Flexural StrengthMPa250 @ 20°C280 @ 1200°CCompressive StrengthMPa2500Modulus of ElasticityGPa330 @ 20°C300 @ 1200°CCoefficient of Thermal Expansion1 x 10-6 in/in °C4.5Thermal Conductivity @ 1200°CW/mK45Poisson's Ratio-0.2Vickers HardnessGPa20-22

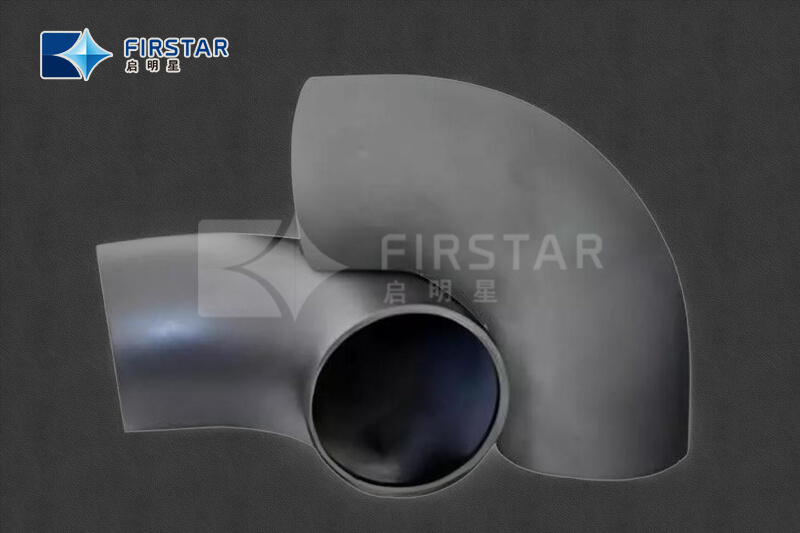

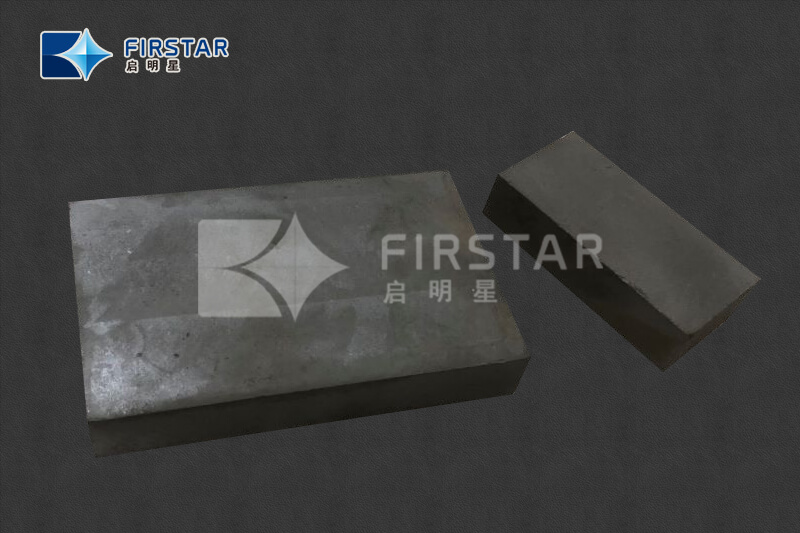

Silicon carbide wear lining tiles/blockInner Lining and Blocks for Industry MaintenanceSiSiC: Moh’s hardness is 9.5 (New Moh’s hardness is 13), with excellent resistance to erosion and corrosion, excellent abrasion – resistance and anti-oxidation. It is 4 to 5 times stronger than nitride bonded silicon carbide. The service life is 5 to 7 times longer than alumina material. The MOR of RBSiC is 5 to 7 times that of SNBSC, it can be used for more complex shapes. Wear resistant ceramic lining is conductive to make improvement of the production performance, the working efficiency, the reduction of maintenance costs and the increase profits.- Excellent wear and abrasion protection property.- Excellent corrosion resistance property- Excellent heat resistance property- Excellent impact resistance property- Excellent for ballistic protectionApplications:- Mining- Mineral processing (mineral beneficiation)- Power generation- Cement- Petro-Chemical Refining and Production- Coal washery- Steel- Defense (personal & vehicle armour).■ Specifications: Item Unit Data Temperature of application ℃1380℃ Density G/cm3 >3.05Open porosity % <0.1 Bending strength -A Mpa 250 (20℃) Bending strength -B MPa 280 (1200℃ ) Modulus of elasticity-A GPa 330(20℃) Modulus of elasticity -B GPa300 ( 1200℃ ) Thermal conductivity W/m.k 45 (1200℃ ) Coefficient of thermal expansionK-1 ×10-64.5 Rigidity /13 Acid-proof alkaline / excellent■ Available Shape and sizes:Thickness: from 6mm up to 25mm Regular Shape: SiSiC tiles, SiSiC Pipe tiles, SiSiC Three Links, SiSiC Elbow, SiSiC Cone Cyclone. Remark: Other sizes and shape are available upon requests. ■ Packaging: In carton box, packed in fumigated wooden pallet with net weight 20-24MT/20′FCL.