and Wear Resistant Products

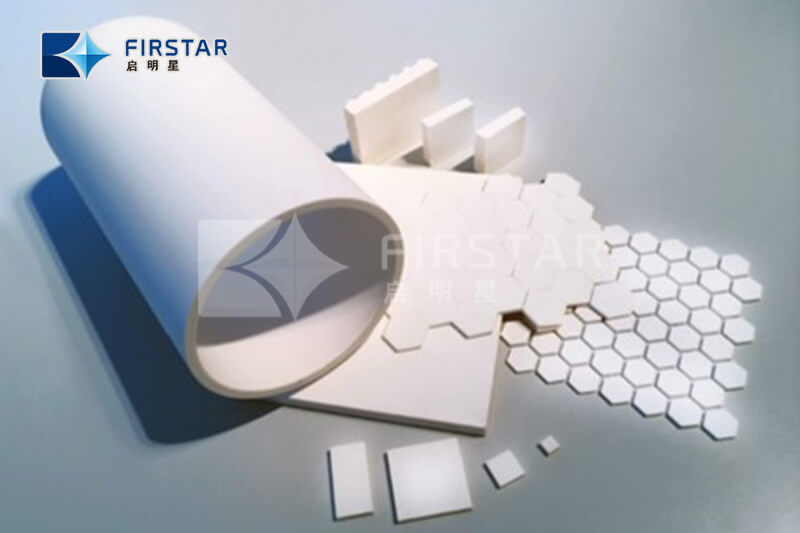

ONLY DIAMONDS ARE HARDERFor aluminium oxide ceramics, ceramic raw materials with an Al 2 O 3 content of more than 80% are used (as high-quality wear protection, in general only ceramics with an Al 2 O 3 content of at least 92%) should be used).It is essentially a single-phase, single-component oxide of corundum crystals, which are bonded by solid-state reactions during sintering.Aluminium oxide is one of the hardest engineering materials and currently the most technically and economically important representative of oxide ceramic materials.Densely sintered it is characterized by:• High degree of strength and hardness• Resistant to high temperatures and corrosionMANUFACTURE AND PROPERTIESThe starting point for the production process is a very pure, synthetic (alpha) aluminium oxide in powder form. The higher the Al 2 O 3 content, the better the mechanical values and the lower the glass phase will be. This leads to an even higher density and to a higher wear resistance.The casting process:• Pressing (highest wear resistance)• Slip casting (demanding geometries)These processes produce the so-called “green bodies” whose consistency is similar to that of chalk. They can now be machined with conventional machines by turning or sawing to obtain specific contours or dimensions. The subsequent sintering process takes place at approximately 1560°C, after which the parts are connected and no longer have any porosity. The resistance values remain virtually unchanged up to 1000°C.APPLICATIONSDue to their high hardness and temperature resistance, aluminium oxide ceramic products are used in extreme wear conditions, often associated with high operating temperatures. The availability in very low wall thicknesses makes thin-walled wear protection coatings possible, especially where weight or construction restrictions prevent the installation of a thicker wall thickness.The wide variety of products allows the coating of all parts subject to heavy wear and high temperatures, such as separators, bunkers, diffusers, sprayers, hydrocentrifuges, chain conveyors, cones, mixers, pumps, chutes, pipes, chutes, gutters or cyclones.

Ceramic Lined OrificesProduct DescriptionIndustrial Ceramics is dedicated to manufacturing hi-tech ceramics for industrial applications. QMX Specialize in the manufacture of wear limiting products, grinding media, liners and engineered ceramics catering to the critical and demanding applications in the Armour, Ceramic Tile, Non-Ferrous, Steel, Power Generation, Power Distribution, Cement, and Mineral & Ore Processing.For pipeline applications requiring precise measurement of volumetric rate or predictable, smooth, QMX offers customized ceramic lined orifice that are more wear resistant than traditional stainless steel orifices. Our Ceramic orifices feature a fabricated steel housing that installs between pipe flanges to securely support the ceramic flow element using a tough, high-adhesion natural and synthetic rubber compound specially selected for the operating environment. Our housings can be configured to fit between flanges of any specification, and are available in stainless steel when required .Fine Grained, high alumina content ceramic offers the best abrasion resistance of any commercial material in metallurgical slurry applications. QMX can choose from a variety of ceramic bodies to find the material with the best properties for each application. To ensure the highest density and dimensional accuracy, the ceramic material is isostatically pressed before machining and firing, The result is a dense, abrasion-resistant and dimensionally accurate orifice.Alumina Ceramic Orifice are the integral part of Variable orifice, Static orifice, Feed Orifice etc. Ceramic Orifice are used to avoid the unwanted punchers and unnecessary downtime for the conveying operations. CUMI designs, manufactures, and supply Alumina Ceramic Orifice for the wear, corrosion and abrasion resistance application. Ceramic Orifice are designed with special dove tail design to ensure to avoid the dislodging of tiles from the steel surface.Ceramic Orifice Benefits:• Longer life of steel structure of the Ceramic Orifice• Prevention of the unwanted punchers• Prevention of frequent maintenance• Less frequent Ceramic Orifice changeoverMaterial Type:- 92%, 95%, 96%, 99% alumina - ZTA(zirconium Toughened Alumina)- RBSiC (Reaction Bonded Silicon Carbide) Applications:• Cement Plant• Steel plant• Mining• Coal based thermal power plantsFeatures:• High strength• Fine finish• Accurate dimensions

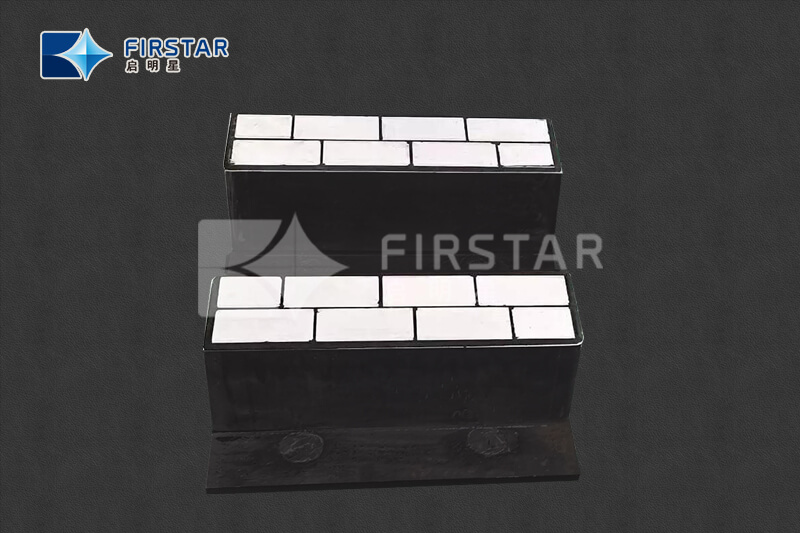

Hex Ceramic Tile Lining KitAbrasion resistant liningOur Alumina abrasion resistant ceramic linings are highly durable and have a significantly longer lifespan compared to lower grade materials typically used for lining or protecting processing and material handling equipment. These linings can outlast these lower grade materials by factors ranging from 3 to 15 times.One common application for our Alumina ceramic linings is in grain transitions. These transitions are areas where grains are moved from one section to another, and they are prone to wear and tear due to the abrasive nature of the grains. By using our ceramic linings, these transitions can be protected and their lifespan can be extended. Similarly, grain spouts, grain elbows, and grain chutes are also susceptible to abrasion and deterioration. Our Alumina ceramic linings provide excellent resistance against wear, allowing these components to withstand the constant flow of grains without experiencing significant damage. This greatly reduces the need for frequent replacements and maintenance. Grain conveyors, hopper bins, and grain valves are other critical equipment in the grain handling industry that can benefit from our ceramic linings. These components are exposed to high levels of abrasion and impact as grains are transported and processed. By installing our Alumina ceramic linings, these equipment can be protected from wear and damage, resulting in improved reliability and reduced downtime. Overall, our Alumina abrasion resistant ceramic linings offer superior longevity compared to lower grade materials commonly used in the industry. By choosing our ceramic linings, businesses can significantly reduce maintenance costs, minimize equipment downtime, and extend the operational lifespan of their processing and material handling equipment. Technical SpecificationsCeramic Material: High Alumina Fine-grain AluminaSurface Finish: As-FiredDimensional Tolerance: ± 1~1.5%Dimension Available: 150x150mm | 300x300mm |300*500mm|500*500mmCategoryHC92HC95HCT95HC99Al2O3≥92%≥95%≥95%≥99%ZrO2////Density (gr/cm3)>3.60>3.65g>3.70>3.83HV 20≥950≥1000≥1100≥1200Rock Hardness HRA≥82≥85≥88≥90Bending Strength MPa≥220≥250≥300≥330Compression strength MPa≥1050≥1300≥1600≥1800Fracture Toughness (KIc MPam 1/2)≥3.7≥3.8≥4.0≥4.2Wear Volume (cm3)≤0.25≤0.20≤0.15≤0.10Alumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkali resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel. Advantages:1. High hardness, its Rockwell hardness is HRA80-90, the hardness is second only to diamond2. Long service life, under the same working conditions, the service life of the equipment can be extended by more than 10 times.3 Light weight, its density is 3.6g/cm3, which can greatly reduce equipment load.4. The bonding is firm and the heat resistance is good. The hexagonal ceramic tile mat is pasted on the inner wall of the equipment with heat-resistant super glue.Application:Widely used in anti-wear material conveying systems in coal, thermal power, steel, cement, mining, port, chemical and other industries, such as coal washing plants, thermal power plants, coal pipes, coal hoppers; coke hoppers in steel plants; mining transfer hoppers; cement plant clinker, cement chute, hopper.

95% zirconia tile is a type of ceramic tile that is made from zirconium dioxide (ZrO2) with a zirconia content of 95%. Here are some of its key features:1. High hardness and wear resistance: 95% zirconia tile has a high Mohs hardness of around 9, which makes it highly resistant to wear and abrasion. This makes it ideal for use in high-traffic areas or where there is a lot of foot traffic.2. Chemical resistance: Zirconia is highly resistant to chemical corrosion and can withstand exposure to acids, bases, and other corrosive substances. This makes it ideal for use in industrial settings or where there is a high risk of chemical exposure.3. Low thermal conductivity: Zirconia has a low thermal conductivity, which means it is an effective insulator. This property makes it ideal for use in high-temperature environments, as it can help to prevent heat loss.4. High fracture toughness: Zirconia has a high fracture toughness, which means it is highly resistant to cracking and chipping. This makes it ideal for use in areas where there is a high risk of impact or mechanical stress.5. Aesthetic appeal: 95% zirconia tile has a smooth, polished surface and a high level of translucency, which gives it an aesthetically pleasing appearance. It is available in a range of colors and finishes, making it a popular choice for use in interior and exterior design applications.Zirconia CERAMIC SPECIFICATIONSZirconium Oxide ZrO294.8 % (min)Density (g/cc)6.05 (min)Hardness (HRA)88 (min)Flexural Strength (Mpa)800 (min)Abrasion Abrasion(cm3)0.05 (max)

Engineering alumina ceramic liner is different standard ceramic tile , designed and tailor-made with CAD Software to suit any type of customer’s components . QMX ceramics offer a range of wear resistant ceramics products that have been engineered to meet the equipment abrasive requirement of special angle , shape,radian,sizes etc.which can be perfectly installed without gaps and fitted for equipment. QMX has experienced to design engineering alumina tiler chute liner like hopper liner , cyclone liner etc. Also will help with your wear problems well .Products Characters :-- Long lifetime and maintenance free operation -- No operation interruption or production losses -- Maximum efficiency of separation --Perfectly fit for equipment without cutting Application industry > mining industry > Cement industry > Coal handling industry > Steel industry > Port industry > Power plant Technical data :Chemical Composition:Al2O3SiO2CaOMgONa2O92~93%3~6%1~1.6%0.2~0.8%0.1%Physical Properties:Specific gravity (g/cc)>3.60>3.65>3.70Apparent porosity (%)000Bending Strength (20℃, Mpa)220250300Compressive strength (20℃, Mpa)105013001600Rockwell hardness (HRA)828588Vickers hardness (HV20)105011501200Moh’s hardness (scale)≥9≥9≥9Thermal Expansion (20-800℃, x10-6/℃)888Abrasion Loss (Cm3)0.250.20.15