and Wear Resistant Products

What Is High Alumina Grinding ColumnAlumina grinding column refers to the high-temperature calcined Alpha alumina powder as raw material, through batching, grinding, powder making, molding, drying, firing, and other processesAlumina ceramic grinding columns make great ceramics, glasses, and enamels in chemical factories and other industries with ball mills, can-type mills, and vibration mills as their main machinery. Al2O3 Alumina grinding cylinder can also be used in these industries: metallic minerals, non-metallic minerals , silicon carbide, talcum, white pigments, cosmetics, cement, building materials.High Alumina Ceramic Grinding Column applicationsApart from grinding usages, you can form rubber-backed ceramic wear liners with our alumina grinding cylinders. The main application for Alumina Ceramic Column is within the mining industry.We suggest Al2O3 alumina grinding cylinders for stirred mills and ball mills preferably. Alumina grinding columns are widely used in different types of ceramics, enamels, glass, chemicals, etc. due to their excellent characteristics such as high strength, high hardness, high wear resistance, large specific volume, small volume, high-temperature resistance, and corrosion resistance.high Alumina Grinding Column advantageThe alumina grinding column has a grinding efficiency and abrasion resistance far exceeding ordinary ball stone and natural pebbles. It is an excellent grinding medium for fine grinding equipment such as ball mills, pot mills, and vibration mills.No abrasion, no corrosion, and no erosion. Alumina ceramic grinding columns resist almost everything. Acid, alkali, chips, extreme heat, and abrupt temperature changes, etc. Al2O3 Alumina grinding cylinder are also pollution-free, easy to clean, and 3-5 more durable than natural stone liners, and 23 times more durable than rubber liners. Installation and milling time are reduced at a minimum, while efficiency is augmented at a maximum.• Wear-resistant low loss• high-temperature resistance• corrosion resistance• High Mechanical StrengthHigh Al2O3 Alumina Ceramic Grinding cylinder specificationSpecification (mm)Diameter (mm)Height (mm)Φ15*151515Φ20*202020Φ25*252525Φ30*303030Alumina ceramic grinding Column Chemical Composition and Physical PropertiesAl2O3≥ 92%≥ 95%Fe2O3≤ 0.01%≤ 0.01%SiO2≤ 5.28%≤ 2.6%Na2O≤ 0.72%≤ 0.44%Hardness9 Mohs9 MohsWater Absorption≤ 0.01%≤ 0.01%Bulk Density≥ 3.6g/cm3≥ 3.7g/cm3Compression Strength≥ 2000 Mpa≥ 2500 MpaWear Loss≤ 0.001%≤ 0.0008%Note: As the grinding media, at a comparable weight with grinding balls, Al2O3 alumina ceramic grinding column have an approx.14% greater surface than alumina ceramic grinding ball.

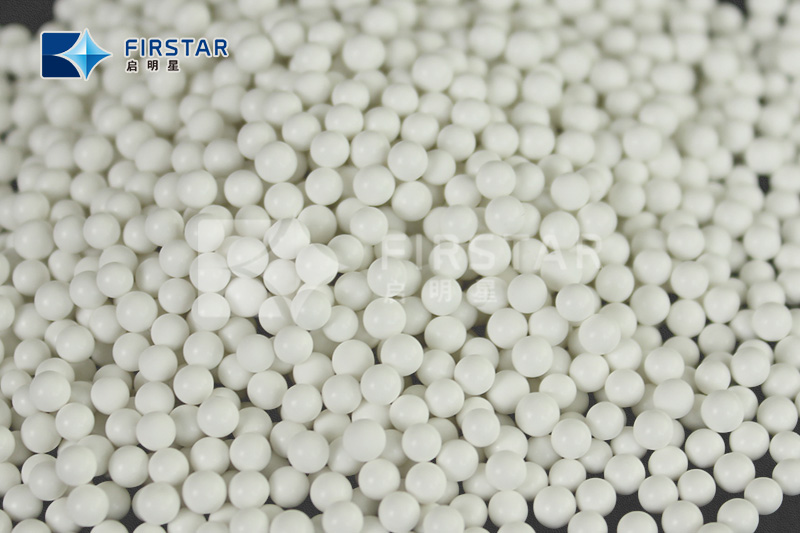

(1) ApplicationAlumina grinding media ball is mainly used in ceramic, glaze, paint, zirconia silicate, aluminum oxide, quartz, silicon carbide, talc, lime carbonate, kaolin, titanium and other materials grinding, and mechanical equipment accessories.(2) PropertiesHigh density, high hardness, low wear loss, regular shape, impact resistance, corrosion resistance, etc.(3) Chemical Property92% Alumina Grinding BallAl2O3(%)92±1Fe2O3(%)<0.25SiO2(%)≤5Mohs hardness9Water absorption<0.01Bulk density(g/cm3)>3.60Wear loss(g/kgh)<1.6Crushing strength(3mm)>1050NSizeØ0.5-60mmSphericity>95%75% Alumina Grinding BallAl2O3(%)>75Fe2O3(%)<0.4SiO2(%)≤20Mohs hardness8Water absorption<0.01Bulk density(g/cm3)>3.15Wear loss(g/kgh)<1.6Crushing strength(3mm)>800NSizeØ0.5-13mmSphericity>95%60% Alumina Grinding BallAl2O3(%)≥60Fe2O3(%)<0.6SiO2(%)≤31Mohs hardness7Water absorption<0.01Bulk density(g/cm3)>2.8Wear loss(g/kgh)<1.6Crushing strength(3mm)>600NSizeØ0.5-13mmSphericity>95%99% Alumina Grinding BallAl2O3(%)≥99Others(%)<0.5Mohs hardness7Water absorption<0.01Bulk density(g/cm3)>3.90Wear loss(g/kgh)<1.6Crushing strength(30mm)>55000NSizeØ0.5-13mmSphericity>95%(4) Standard Dimensionø0.5-1mm, ø1.5mm, ø2mm, ø2.5mm, ø3mm, ø3.5mm, ø4mm, ø5mm, ø6mm, ø8mm, ø10mm, ø13mm,ø15mm, ø20mm, ø30mm, ø40mm, ø50mm, ø60mm(5) PackageDifferent package as to meet different customer’s requirements.Wooden Crates Drum Plastic Pallet Bulk Packing

This alumina grinding media possesses excellent thermal properties. So you can grind down to the particle size you need to achieve.Better for some applications than porcelain, flint pebbles, or natural stones, Ultraming Alumina grinding balls are precisely engineered, down to the nanometer.Because when it comes to your ball milling process, every nanometer counts.DESCRIPTIONPROPERTIESShapeSpherical, cylindricalColorWhiteAlumina60%, 75%, 92%Ball size0.5-30 Rolling Type25-60mm Pressed TypeHardness7-9MohsSelf Wear Rate≤0.08g/kg.h

-High density-High fracture toughness-Large Specific density-Wear resistant,anti corrosion-PPM Grade wear loss Applications:-Suitable for Electronic ceramic,ink,paint,pigments,coating,dyes,food,cosmetic,pharmaceutical industry which require high wear resistance and contamination-free from grinding media-Suitable for fine particle size production as high compression strength and narrow size distribution- Suitable for nano particle size production industry. Chemical PropertyYTZ yttria zirconia grinding beads propertiesItemsTypical ValuesCompositionWt%94.8% ZrO25.2% Y2O3Packing Densitykg/L3.7~3.9Bulk Densityg/cm35.95~6.0Hardness (HV)GPa>8Wear loss(g/kgh)≤1.3Crushing StrengthN(⌀5)≥16000Sphericity%≥95Standard sizemm0.3-30Packing25kgsPackageDifferent package as to meet different customer’s requirements.25kg/pails+Wooden Crates