and Wear Resistant Products

QMX Wear PlateIncrease the life and performance of your operational assets.Wear Plates are designed and manufactured for their specific intended application, ensuring the correct plate is always recommended and installed. In addition to the sale of wear plates, HICTECH offers installation capabilities which deliver exceptional customer satisfaction and value. Facilitated by our experienced and reliable onsite service division, we will take control of your whole project, from the conception and evaluation stage, through to the manufacture, delivery, installation, maintenance and ongoing after sales service/support. Wear plates are engineered to suit each application and have various fixing options, steel studded backing plates, weld on options and direct substrate bonding.Wear PlatesWear Plates are manufactured to the highest quality standards and specifications, making them far superior to any other product in the market.Features:Superior wear characteristicsDampens impactNoise reductionReduces downtimeLow cost per tonne ROIFit for purposeApplications:ChutesHoppersTransfer pointsCrushing and screeningMillingTrain and ship loadersCompositionThicknessesTypeZirconia Toughened Alumina37mm-63mmVulcanised rubber / studded steel plateAlumina 92% / 95% Al20337mm-63mmVulcanised rubber / studded steel plateAlumina 92% Al203 / Natural Rubber8mm-63mmHexagonal, cubed, cylinder, tileAlumina 92% Al203 / High Tensile Polymer10mm-63mmHexagonal, cubed, cylinder, tilePolyurethane3mm-20mmComplete cast

Engineered CeramicsQMX Premium Alumina|Ceramic Wear Lining Tiles for Various Abrasion Application QMX Premium Engineered Ceramics provide excellent impact and wear resistant characteristics for superior longevity in the harshest applications. ManufactureQMX premium alumina products are manufactured to ISO9001:2015 with high purity ultra-fine powders, using the most advanced technologies and international best practice. QMX integrates research, design and manufacturing to produce the highest quality products that provide excellent impact and wear resistant characteristics for superior longevity in the harshest applications.QMX premium alumina ceramics provide maximum protection for applications such as transfer chutes, sumps, centrifuges, screens, cyclones, pipes, bins, hoppers and pulley lagging across various industries. Aluminas (aluminum oxide, Al2O3) are the most commonly used technical ceramics for both general use and specialised applications. Grades are selected to fit the application environment. Alumina compositions and microstructures can be formulated to meet the specific performance requirements of more demanding applications.QMX premium alumina ceramics are manufactured by blending and mixing specified ratios of high-quality raw materials such as alumina powders, oxides, lubricants, dispersion agents, binders and water using a ball mill method. The slurry then goes through a spray drier before the pressing stage. Low percentages of organic binders allow the alumina particles to bond together and form a green un-sintered body during the pressing stage. Once pressed to size, pre-heating takes place followed by sintering through a tunnel kiln. Sintering temperatures and times are strictly followed to ensure binder burn out is optimised and that explosive spalling does not take place.HardnessAlumina ceramics are very hard wear-resistant material with a Mohs hardness of 9 (compared to diamond which is 10), making it an ideal and cost effective material for wear protection components. QMX Alumina’s are manufactured in a range of shapes and sizes in both 92%, 95% and ZT Alumina. The properties of alumina are further enhanced via the addition of densification aids that make up the other 5%-8%. QMX Premium Zirconia Toughed Alumina (ZTA) has a unique crystal structure which combines extreme strength, high fracture toughness, and excellent wear resistance. It is ideal for extreme mechanical environments, particularly impact prone applications.Features:Pre-engineered shapesAbrasion resistanceTemperature resistanceImpact resistanceHardness and durabilityCorrosion resistanceVarying gradesQuality assuredUsabilityMarkets:Coal handling plantsSteel millsIron ore beneficiation plantsHard rock concentratorsPower generationPortsAppliancesLaboratoriesConveyorsCompositionThicknesses/DiameterTypeZirconia Toughened Alumina25mm-50mmStd tile sizesAlumina 92% / Al2033mm-75mm pre-engineeredStd tiles, half tiles, pipe tiles, hex matts, pulley lagging tiles, monolithic sleeves, cylinders, cones, tile setsAlumina 95% Al2033mm-50mmStd tile sizes, half tiles, pipe tilesReaction Bonded Siliconized Silicon Carbide (RBSiC)5-50mm pre-engineeredStd tiles, monolithic sleeve, cylinders, cones, tile sets

Wear resistant ceramic which are mainly composed of at least 90% Al2O3 are the most widely used in the world today.Our products are made from strictly selected alumina powder with uniform particle sizes and low CaO content.Wear resistant ceramics can be made through common dry press or isostatic pressing process and then sintering them at high temperature in the kiln. They are desirable lining materials for high wear equipment due to precise dimensions, high density,high alumina content,good flatness and stable quality.CategoryHC90HC92HC95HCT95HC99HC-ZTAZrO2Al2O3≥90%≥92%≥95%≥ 95%≥ 99%≥75%/ZrO2/////≥21%≥95%Density>3.50g/ cm3>3.60g/cm3>3.65g/cm3>3.70g/cm3>3.83g/cm3>4.10g/cm3>5.90g/cm3HV 20≥900≥950≥1000≥1100≥1200≥1350≥1100Rock Hardness HRA≥80≥82≥85≥88≥90≥90≥88Bending Strength MPa≥180≥220≥250≥300≥330≥400≥800Compression strength MPa≥970≥1050≥1300≥1600≥1800≥2000/Fracture Toughness KIc MPam 1/2≥3.5≥3.7≥3.8≥4.0≥4.2≥4.5≥7.0Wear Volume≤0.28 cm3≤0.25cm3≤0.20cm3≤0.15cm3≤0.10 cm3≤0.05cm3≤0.02cm3Notes: We can make alumina wear tile according to your requirement.FeaturesHigh hardnessRockwell hardness of high alumina ceramics is up to HRA80-90 which is second only to diamond and far exceeds wear-resistant steel stainlessExcellent wear resistanceThe wear resistance of high alumina ceramics is 266 times that of manganese steel and 171.5 times that of high chromium cast iron.According to our investigation & follow-up to the clients, the service life of equipment can be prolonged over 10 times under the same working conditions.Corrosion resistanceHigh alumina ceramics are inorganic oxides with extremely stable molecular structure and no electrochemical corrosion, thus they can resist erosion of acid, alkali, salt solutions and organic Solvents.ThermostabilityWorking temperature of high alumina ceramics can be as high as 1400℃.Good self-lubricityHigh alumina ceramics have the properties of self-lubricity and inadhesion, the roughness is only 1/6 that of steel pipes thus less flow Resistance.Light weightThe density of high alumina ceramics is about 3.6g/cm3, which is only half that of steel, thus easy for construction and installationWear solutions we provideThis is a complex process.Our engineers understand wear problems and specifysolutions to meet your operational environment. Material properties,tolerances, flatness,attachment methods, and material costs are all considered in a wear solution.Applications• Chutes/Hoppers• Classifier Cones• Cyclone Separators• Elbows• Fan Housing & Blades• Lined Piping• Nozzles• Wear PanelsMarkets• Coal-fired Power Generation• Abrasive Material Handling• Chemical Processing• Food Processing• Iron/Steel Manufacturing• Mineral Processing• Powder/Bulk Solids Conveying• Pulp & Paper Manufacturing• Pulverizing & Grinding

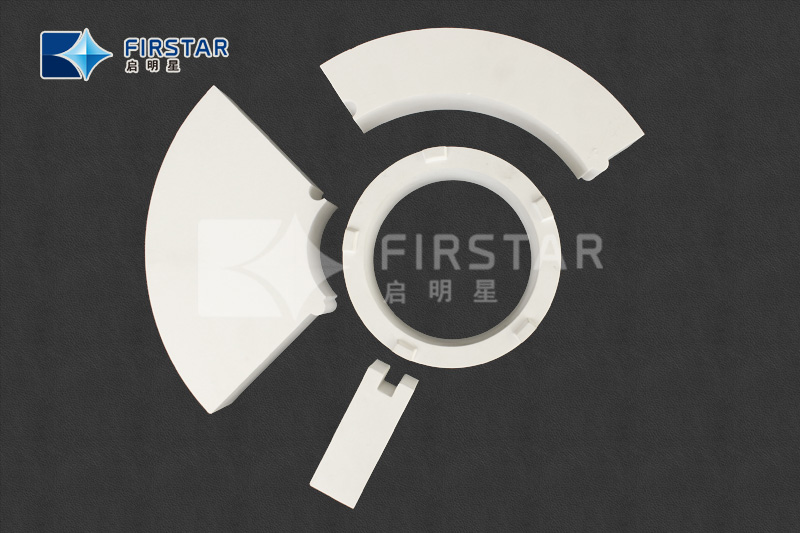

Ceramic cyclone parts alumina spigot apexThe material cyclone suffered serious abrasion and impact when it separated the material particle, like coal, gold, iron and ext. because of high speed material conveying. It’s very easy to wear out to leak the material from cyclone and a suitable wear protection solution for material cyclone is very necessary.ULTRAMING used the ceramic liners lined into the inner wall of the cyclone to get the wear & impact protections. It has been turned out it’s a very good wear solution for material cyclones.Also, we can design different shape and thickness ceramic liners for the cyclones according to different working conditions. Custom cyclone can be made according to client’s drawing.Applications:1.Coal2.Mining3.Cement4.Chemical5.Steel

1. ApplicationAlumina ceramic cylinder bushing liner / lining tube / sleeve lining with high abrasion resistance are widely used for serious abrasive environments, such as chute liners, cyclone liners, conveyor skirt liners, processing piping liners, hopper or silo liners, screen equipment liners in the industries including ,but not limited to: ♦ Coal Preparation Plants ♦ Coal Fired Power Stations♦ Mineral Processing Plants ♦ Cement Plants♦ Chemical Plants ♦ Steel & Iron Plants♦ Railway Stations ♦ Ports 2. PropertiesHigh density, high hardness, low wear loss, regular shape, impact resistance, corrosion resistance, etc. 3. Standard DimensionOD12MM, ID10.2MM, THICKNESS: 8MM, H4.5MMdifferent sizes for your selectionProductIDODThicknessLengthRDegreeStraight Tube7610615150-250//Straight Tube10014020305//Straight Tube15018517.5150-250//Straight Tube15218215150-250//Straight Tube20024020305//

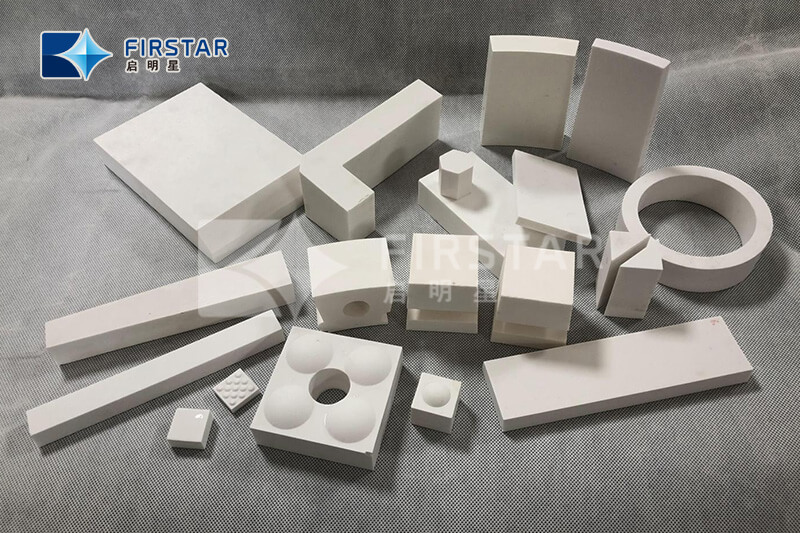

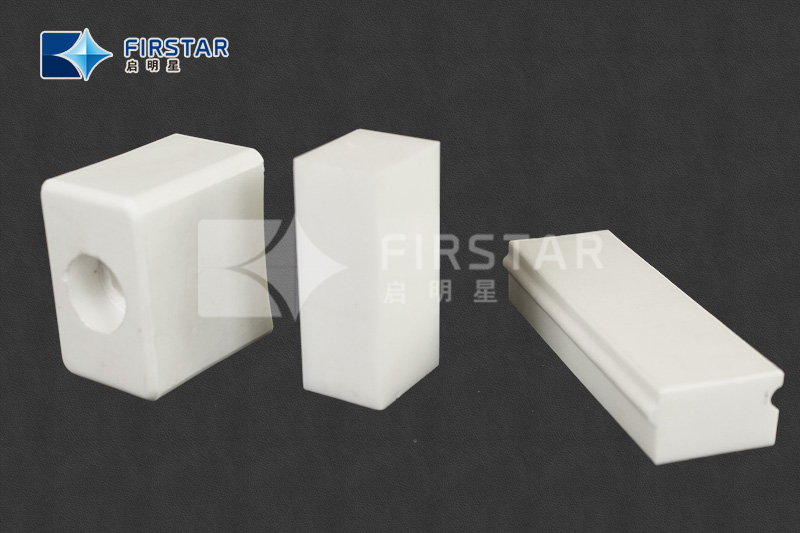

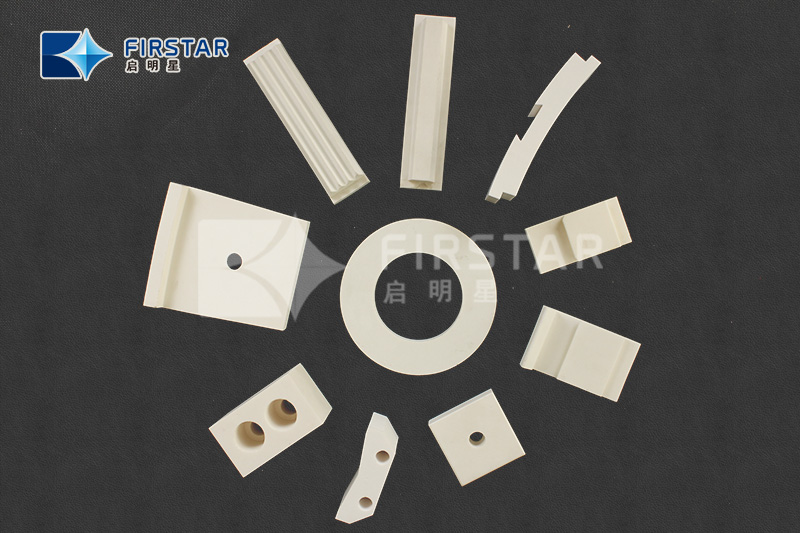

Wear resistant pre-engineering tile in a variety of geometric shapes from simple to complex,the ceramics can be engineered or mould to specific shapes to customer's requirement.Ceramic lined equipment like pipes,bends,chutes,hoppers,bunkers, etc. Alumina ceramic liner has excellent abrasion resistance,hard resistant,corrosion resistance,it is widely used in the mining,power plant,steel plant,cement industries like chutes, hopper,bunker,cyclone,convey belt, etc. This alumina ceramic product make cost effective performance like reduce un-necessary down time and maintance,and prolong the equipment from quick abrasion.Engineered linings product is a speciality We can supply and install a wide range of pre-engineered alumina ceramic tiles tailor-made to suit any type of application . CAD software is used to design wear resistant lining for customer's components. Machining before sintering makes us able to provide linings with complex and 3 dimensional shapes as a cost-effective solution. Which will fit nearly any geometry , A well designed engineered lining system different from standard ceramic tile bricks will make equipment with special angle without gap, so it avoid materials wastage and machines wear damage . Feature· Excellent corrosion resistance property· Easily handled size and weight· Excellent heat resistance property· Excellent impact resistance property· Fast and safe installation· Lower production and maintenance costAlumina Ceramic Advantages· Professional technical team to afford CAD designs· Professional installation team to afford install service· Well established process as per international standards· Accept the standard and pre-engineered tiles QMX type of ceramic tiles-Alumina plain Tile-Pipe tile-Radius tile-Curved tile-Weldable/weld-on tile- engineered tile

Customized Ceramic Wear TilesQMX offers a full range of shapes and sized ceramic tiles for your severe wear lining applications. QMX can offer standard sized tiles (square and rectangular), hex tiles as well as custom shapes and sizes for your demanding application.QMX offers a complete material portfolio for these ceramic wear tiles including; several grades of Aluminum Oxide 92%, 95%, 99%, Zirconia Toughened Alumina(ZTA), Zirconia, Reaction Bonded Silicon Carbide as well as Sintered Silicon Carbide for your most extreme corrosion, abrasive and wear environments.Please contact us and allow our application engineers the opportunity to work with your engineering team to recommend the right advanced ceramic materials for your toughest challenges.

QMX wear and abrasion resistant linings reduce downtime and maintenance and are marketed throughout the world. These wear resistant linings serve a variety of processing equipment including hydraulic and pneumatic components and pipes handling large quantities of bulk materials. We offer wear solutions for iron and steel, mining, power, cement and other industries. We are your source for total custom piping solutions too! Complete planning, design, pricing, fabrication and installation. We know pipe!