and Wear Resistant Products

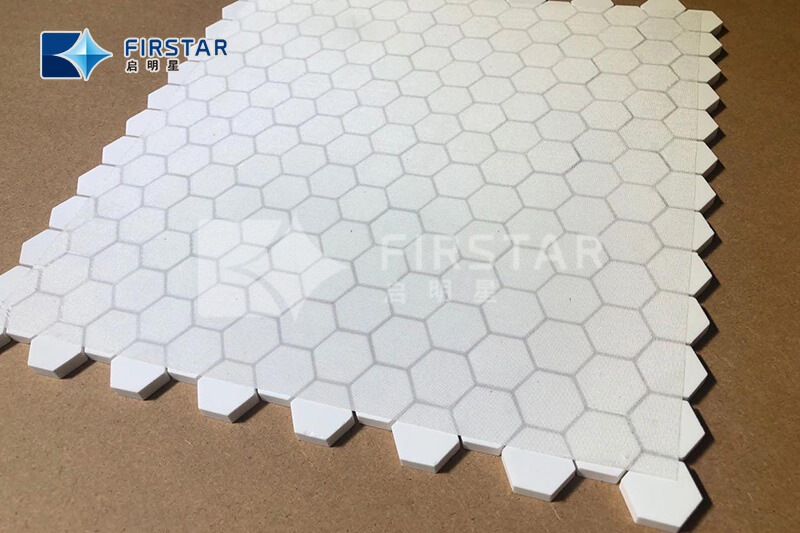

Detailed description:QMX Pulley lagging is made through hundreds of individual ceramic lining pieces vulcanized into durable rubber plates, every applied ceramic lining tile have raised dimples for abrasion resistance.Generally,with the conveying pressure , thousands of salient point in alumina ceramic liner tile can have a positive traction to prevent slipping, extending the life of the roller conveyor.Which makes the drive roller life ten times more than the original drum .At the same time,each ceramic sheet has grooves spaced in a certain distance, enabling foreign matter like dust, dirt on the drum discharged along the trench, which makes the drum with a unique self-cleaning function, especially suitable for wet working environment.Alumina ceramic mosaic tile have various sizes available.Alumina ceramic characters: > High hardness with Moh's hardness 9 grade> High abrasion and chemical resistance> Special dumps designed for more wear resistance> Light weight with various sizes

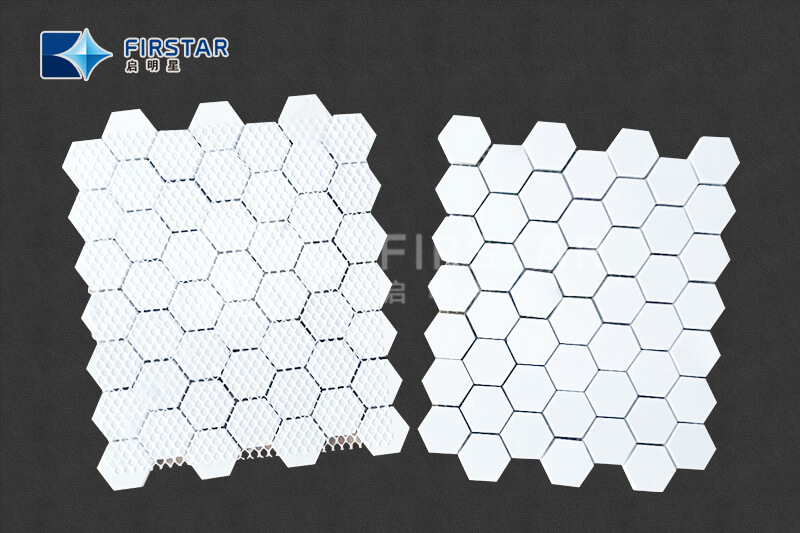

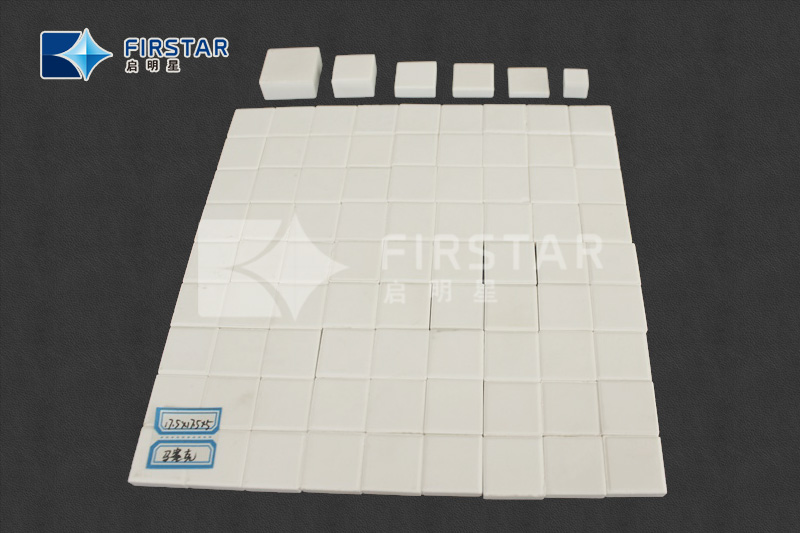

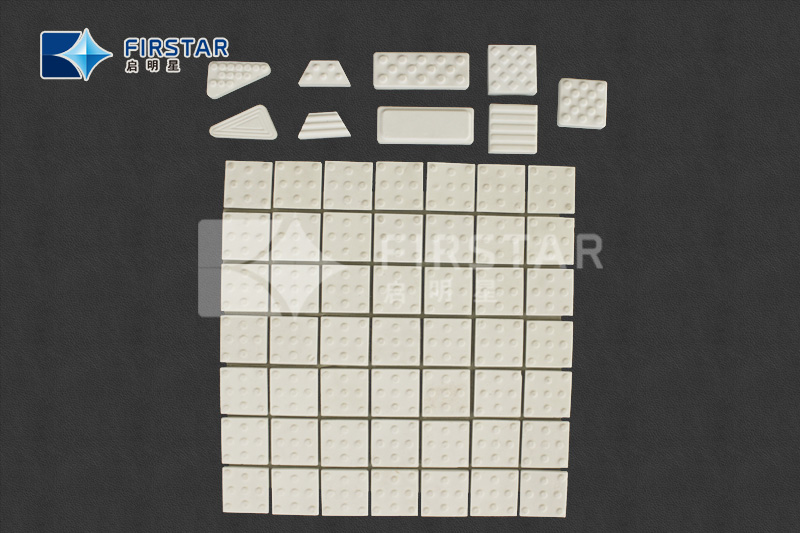

High Alumina Ceramic Tiles Mats Product Description:Alumina Ceramic square tile mats is combination of high hardness alumina mosaic tile and backed silk , paper or net .the low friction , smooth surface prevents materials build-up in low inclination installations. The square ceramic tiles make it possible to bend the sheeting which makes it perfect protection for con-ave and convex surface .the sizes of ceramic square tile matted can be easily be adjusted by bending the sheeting and cutting it in between the ceramic tiles .this alumina ceramic square tile matted has advantages including : no specialist tools required, can be applied to most substrates . Convenient design for fast and easy application .Alumina ceramic tile mats advantages :> High hardness with Moh’s hardness 9 grade> High abrasion and chemical resistance> Easy installation by epoxy resin glue water> Easy mending if someone hex tile drop off> Various of alumina ceramic hex sheet size availableSizes:L*WThk.Ceramic mats(stick on Sticker/nylon Mesh/Acetate/Paper10*103--10mm150*150mm17.5*17.53--15mm150*150mm, 300*300mm,300*500mm20*204--15mm300*500mm25*254--10mm/12*126--25mm/12.5*12.56--25mm/

QMX Ceramic mosaic mat are of 2 shapes, square alumina ceramic mosaic tiles and alumina ceramic hexagon mosaic mat, inlaid on the surface of equipment and work area by rubber or glue. They are designed to protect equipment and work area by abrasion resistance, acid and alkali corrosion resistance and other characteristics. Alumina ceramic mosaic tiles can be used in flat areas and curved surfaces. DescriptionCeramic mosaic mat as wear resistant liner materials and easy fixing process is popular in the field of wear-resistant. It is widely used as wear liner for pulley lagging, rubber ceramic plate and kinds of irregular surface of equipment and facilities. It can be easily installed and fixed by special adhesive. Popular Sizes Of Alumina Ceramic Mosaic Tile MatsPopular sizes of the flat alumina tiles as follows:500*500*6mm 4mm ceramic+2mm rubber500*500*8mm 4mm ceramic+4mm rubber500*500*10mm 6mm ceramic+4mm rubber500*500*14mm 10mm ceramic+4mm rubber500*500*20mm 15mm ceramic+5mm rubber500*500*25mm 20mm ceramic+5mm rubber500*500*30mm 25mm ceramic+5mm rubber Product Features1) Suitable for lining on irregular surfaces2) High strength3) High hardness4) High density5) Acid and alkali resistant6) Corrosion resistant7) Good impact resistance

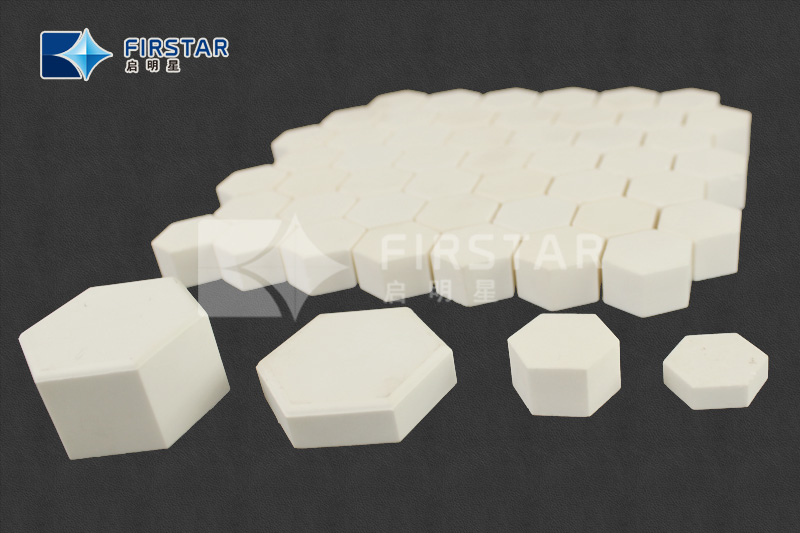

Product Name:Alumina Ceramic Hexagonal TilesProduct H.S Code:690912Product Materials:AluminaProduct Color:WhiteCertificate:ISO9001Customized:AvailableProduct Packaging:Cartons and Pallet Product Details:QMX alumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel Size of Alumina Mosaic Ceramic ( square / Hex.) Tiles

alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Wear-resistant hex mats prevent erosion and abrasive wear in conveying and bulk material handling systems. Their flexible design allows for lining of intricate systems including fan blades, chutes, hoppers, and more.Order quantities may range from one box of ten mats up to container loads. Mat Size RangeThickness Range: 1/8” through 1” (Metric: 3-25mm)Size Range: 6” x 6”, 12” x 12” 12”x20” (Metric: 150x150mm, 300x300mm, 300x500,mm)Technical SpecificationsCeramic Material: 92%, 95% Alumina Surface Finish: As-FiredDimensional Tolerance: ±1%L*WHNote10*103--10mmBulk pieces or Mats17.5*17.53--15mmBulk pieces or Mats20*204--15mmBulk pieces or Mats25*254--10mmBulk pieces or Mats12*126--25mmBulk pieces or Mats12.5*12.56--25mmBulk pieces or Mats

High Alumina Ceramic Tiles Mats Product Description:Alumina Ceramic square tile mats is combination of high hardness alumina mosaic tile and backed silk , paper or net .the low friction , smooth surface prevents materials build-up in low inclination installations. The square ceramic tiles make it possible to bend the sheeting which makes it perfect protection for con-ave and convex surface .the sizes of ceramic square tile matted can be easily be adjusted by bending the sheeting and cutting it in between the ceramic tiles .this alumina ceramic square tile matted has advantages including : no specialist tools required, can be applied to most substrates . Convenient design for fast and easy application .Alumina ceramic tile mats advantages :> High hardness with Moh’s hardness 9 grade> High abrasion and chemical resistance> Easy installation by epoxy resin glue water> Easy mending if someone hex tile drop off> Various of alumina ceramic hex sheet size availableSizes:L*WThk.Ceramic mats(stick on Sticker/nylon Mesh/Acetate/Paper10*103--10mm150*150mm17.5*17.53--15mm150*150mm, 300*300mm,300*500mm20*204--15mm300*500mm25*254--10mm/12*126--25mm/12.5*12.56--25mm/

Product Name:Alumina Ceramic Hexagonal TilesProduct H.S Code:690912Product Materials:AluminaProduct Color:WhiteCertificate:ISO9001Customized:AvailableProduct Packaging:Cartons and Pallet Product Details:QMX alumina ceramic Hexagonal Mat, paste into square mosaic ceramic sheet as an excellent wear - resistance materials and easy fixing method are popular in market. Alumina Ceramic Tile is of high wear resistance, acid and alkli resistance, effectively prolong the service life of equipment and considered to be the best choice of anti-wearing and anti-corrosion material; Wear resistance of ceramic is 266 times than that of special manganese, 171.5 times to high chrome cast iron; Hardness is much higher than that of wear-resistant steel and stainless steel Size of Alumina Mosaic Ceramic ( square / Hex.) TilesL*WHNote10*103--10mmBulk pieces or Mats17.5*17.53--15mmBulk pieces or Mats20*204--15mmBulk pieces or Mats25*254--10mmBulk pieces or Mats12*126--25mmBulk pieces or Mats12.5*12.56--25mmBulk pieces or Mats

QMX manufactures a full range of high-density, fine-grain, wear-resistant alumina ceramic hex mats (hexagonal tiles). Our alumina ceramic is next to diamond in hardness, is 12 times more wear-resistant than carbon steel, and exhibits excellent corrosion resistance.Wear-resistant hex mats prevent erosion and abrasive wear in conveying and bulk material handling systems. Their flexible design allows for lining of intricate systems including fan blades, chutes, hoppers, and more.Order quantities may range from one box of ten mats up to container loads. Size RangeThickness Range: 3-25.4mmSize Range: 150x150, 250x250, 300x500, 500x500 mmTechnical SpecificationsCeramic Material: 92%, 95%,99%, ZTASurface Finish: White Dimensional Tolerance: ±1%Maximum Temperature Limit: 1,500° C

Ceramic mosaic is widely used as a lining (facing) tile in the conveyor equipment to protect the drive pulleys of belt conveyors from wear, increases the tape engagement ratio, excluding its slippage. The mosaic mats consist of small mosaic tiles glued to acetate silk or PVC mounting film. Standard mats are 150x150, 300x500 and 500x500 mm. Standard thickness is 3-12 mm. The mats consist of a square tile of 10x10 or 20x20 mm, or a hexagonal tile of SW20 mm. Special sizes are on the Customer's request. Alumina content: 92%, 95% and 99%Packing: 25kg pp bag on pallet

The rubber-ceramic lining of pulley is particularly suitable in cases where slippage and excessive wear make normal rubber lining ineffective. Alumina ceramics tiles allow to maintain the correct position of the belt, even in conditions of high humidity, heavy pollution and abrasive impact. Also, by varying the thickness of the ceramic elements and the total thickness of the lining, it is possible to compensate the difference in diameters of the pulleys A. Rubber:1. Material: NR&BR2. Density: 1.15 g/sm3. Tensile strength: 24 MPa4. Shore hardness: 60±55. Elongation: 360%6. Wear lost: 85 mm37. Ageing coefficient: 0.87 (70C°x48 hours) B. Alumina ceramics:1. Material: Al2O3 92-95%2. Density: 3.6 g/cm3 3. Colour: wight4. Wear lost:<0.20cm35. Hardness: Mohs 9