A cyclone is a specially designed system used to separate materials using centrifugal forces. The materials fed into a cyclone are typically hard and the environment within a cyclone is inherently highly abrasive. Hence wear inside a cyclone is an operational hazard. QMX Ceramic Engineering have the materials and expertise to be able to minimize wear of your cyclone linings and thus reduce downtime and increase efficiency.

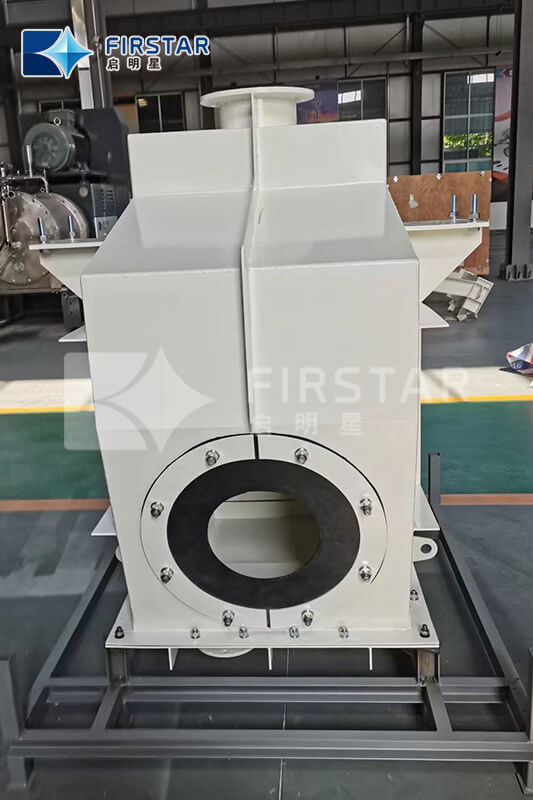

The main body of the cyclone consists of a reducer or a cone shaped liner tapering from a larger diameter to a smaller one down its length.

Wear Resistant Solutions for Cyclones

Since the materials separated in a cyclone are highly abrasive, it is important to have a cyclone lining that stands up to rigors of the job. Ultra High Purity Alumina can be used to increase cyclone working life and performance and can be custom shaped to suit all geometries; from the pipe work leading to the inlet, the vortex finder and apex outlet, to the conical heart of the cyclone.

Cyclone Components Commonly Subject to Wear

There are many components within a cyclone assembly that are subject to high wear conditions. Taylor Ceramic Engineering can supply many of these in wear resistant materials to extend component life. Some of the parts that we typically supply include:

· Cylindrical & Reducing Liners

· Inlets

· Outlets

· Spigots

· Inserts

· Upper, Mid & Lower Cone Sections

· Vortex finders

· Virtually any surface that undergoes wear!

Wear Resistant Lining Formats

A range of wear resistant lining techniques can be used; from monolithic inserts to tiled sections.

Monolithic Sections

QMX is uniquely positioned to be able to manufacture small and large monolithic shapes in short time frames. These sections can be custom made to suit your precise requirements.

Monolithic sections have the advantage that they are much faster to install, thus reducing downtime.

Tiled Sections

Because most surfaces associated with a cyclone assembly are curved, Taylor Ceramic Engineering is able to engineer tiles that conform to the exact shape required.

Flat tiles on curved surfaces often leave a series of flats radially around the internal surface of the cyclone. This not only interrupts material flow but increases wear on the tiled surfaces and thus reduces equipment life. However, using engineered curved tiles that conform to the required shape reduces the discontinuities and increases material flows and hence the equipment efficiency.

| Category | HC90 | HC92 | HC95 | HCT95 | HC99 | HC-ZTA | ZrO2 |

| Al2O3 | ≥90% | ≥92% | ≥95% | ≥ 95% | ≥ 99% | ≥75% | / |

| ZrO2 | / | / | / | / | / | ≥21% | ≥95% |

| Density | ≥3.50g/ cm3 | ≥3.60g/cm3 | ≥3.65g/cm3 | ≥3.70g/cm3 | ≥3.83g/cm3 | ≥4.10g/cm3 | ≥5.90g/cm3 |

| Water Absorption | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% | ≤0.1% |

| HV 20 | ≥900 | ≥950 | ≥1000 | ≥1100 | ≥1200 | ≥1350 | ≥1100 |

| Rock Hardness HRA | ≥80 | ≥82 | ≥85 | ≥88 | ≥90 | ≥90 | ≥88 |

| Bending Strength MPa | ≥180 | ≥220 | ≥250 | ≥300 | ≥330 | ≥400 | ≥800 |

| Compression strength MPa | ≥970 | ≥1050 | ≥1300 | ≥1600 | ≥1800 | ≥2000 | / |

| Fracture Toughness KIc MPam 1/2 | ≥3.5 | ≥3.7 | ≥3.8 | ≥4.0 | ≥4.2 | ≥4.5 | ≥7.0 |

| Wear Volume | ≤0.28 cm3 | ≤0.25cm3 | ≤0.20cm3 | ≤0.15cm3 | ≤0.10 cm3 | ≤0.05cm3 | ≤0.02cm3 |

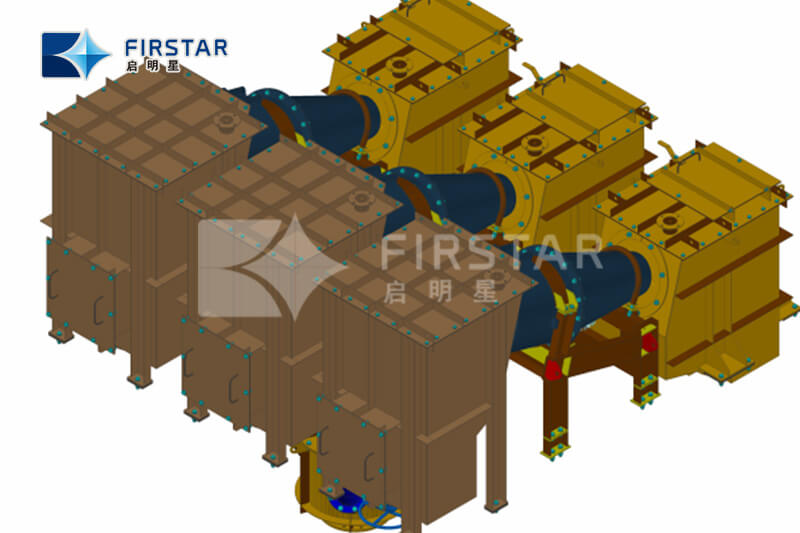

Layout of Drawing: