CERAMIC LINED COMPONENTS AND BENDS

Hard & Compact ; Smooth & Inert ; Withstands High-Abrasion & Corrosion ceramic wear linings

In any of the process industries, especially steel and cement, corrosion and abrasion lead to significant downtime of the plant. Further, the useful life of the equipment itself may get impaired because of high abrasive nature of the materials being used. Thus, ‘wear mechanism’ results in shutdown, replacement, etc., which is costly, resulting in loss to the tune of millions of rupees. For resistance to wear, ceramic lined bends, straight pipes, etc., are ideal.

FEATURES

High resistance to all types of chemicals

High resistance to sliding abrasion

Non wet ability and smooth surface results in easy flow of materials

Can withstand temperature of up to 200°C

Smaller ID of 100 mm can also be manufactured

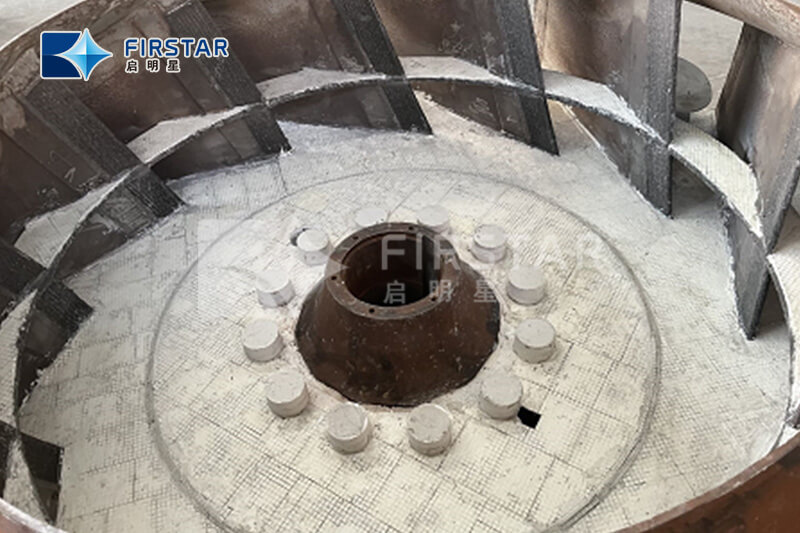

COAL DISTRIBUTOR

HYDRO CYCLONES FOR COAL WASHING PLATE