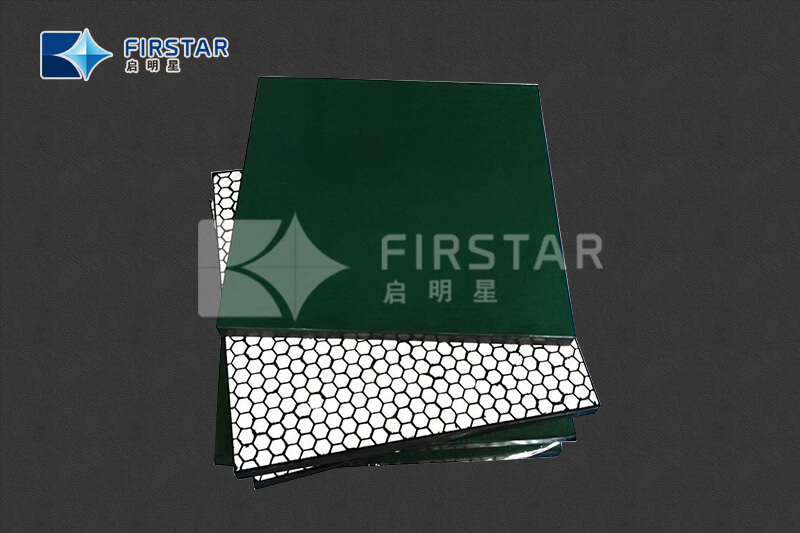

Cold Bonded Wear Panels

QMX Wear Panel solutions are ideal for a wide variety of mining, mineral processing and material handling for protection against extreme wear.

Application

Typical application examples:

· Chutes

· Cyclones

· Launders

· Pipes and tanks

· Conveyor transfer points

· Screen beams, underpans and components

· Vibratory feeders

Key features and benefits

· 92% Aluminium oxide material.

· Rubber compound blended with CN polymers.

· Buffed CN bonding layer and buffed edges.

· Manageable size and weight. Strip width 250mm makes it easy to install.

· Fire resistant and antistatic (FRAS) rubber compound available.

· Low sulphur rubber.

· Ceramic tiles bonded to rubber on all sides (except top surface).

· Supplied in square panels 500mm x 500mm.

· Extreme wear resistance.

· Outstanding adhesion to ceramic tiles, rubber and metal.

· For optimum cold vulcanised adhesion.

· Can be used in above and below ground applications.

· Stable rubber hardness with age.

· Resists tile cracking and pull out.

· Easy to install.

Rubber,Ceramic&Steel Specification

S.No. | Material | Attributes | Properties |

| 1 | Ceramic Tiles | Material | 92%, 95%, T95%,99%, ZTA |

| 2 | Rubber | Component | Natural rubber, nitrile-butadiene rubber ,Flame Retardant ,others |

Density | ~1.4g/cm3 | ||

Tensile strength at break | ≥10.6Mpa | ||

Elongation at break | ≥350% | ||

Shore Hardness | 45-65 | ||

Adhesive between tile and rubber | ≥3.8 Mpa | ||

Adhesive between rubber and equipment | ≥3.58Mpa | ||

Thermal conductivity.(normal temperature) | 2w/m·k | ||

Aging period | ≥15 Years | ||

Working temperature | -50ºC - 200ºC | ||

| 3 | Steel plate | Material | Q235A |

Density | 7.85g/cm3 | ||

Thickness | 3-10mm | ||

| 4 | Adhesive | Appearance | Brown glutinous liquid |

Solid content | 20±3% | ||

Viscosity | ≥2.5 Mpa | ||

Peel strength | 48h N/2.5cm≥120 | ||

Compressive strength | ≥850 Mpa | ||

Working temperature | -20ºC - 100ºC |