Wear Resistant Rubber Ceramic Panels is new generation composite panels, a combination of wear resistant alumina ceramic cylinders/ceramic tiles vulcanized in resilient rubber base. The alumina ceramic surface provides exceptional resistance to wear, while the elastic property of the rubber effectively dampens the impact forces which can crack the ceramics. Rubber also helps to substantially reduce the vibrations, sounds, and the impact shock generated from impacting rocks. Laid out in zigzag and brick pattern, ceramic tiles/cylinders is an excellent feature for handling large material volumes at different angles without developing a wear pattern. As excellent impact and wear resistant material,The panel is suitable for feeders, chutes, bins, transfer points, in conveyor systems, screen feed plates, mill discharge chutes, bunker etc. The major applicable industries are Coal fired power plants, cement plants, blast furnace plants and host of other industries which requires high impact abrasion resistant surfaces.

| Type of Ceramics | Rubber | Steel/Metal |

| 92% Alumina | Natural rubber Hardness 60 | A235A |

| 95% Alumina | ||

| 99% Alumina | ||

| ZTA | ||

| Zirconia |

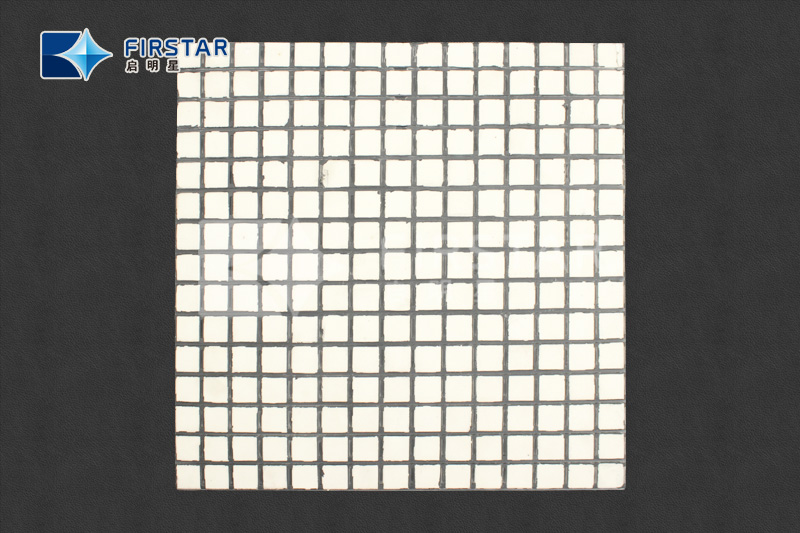

Hex Tile mats Regular sizes:

| Panel Size | 300×300,250×250,500×500,600×600mm |

| Ceramic size | 19x19, 21x21, 40x40 Hex tile |

| Alloy Steel Size | alloy steel plate with thickness ranging from 3 mm to 10 mm |

| Rubber Thickness | Depends upon the impact stress expected. |

| Remark | metal+rubber+ceramic / rubber+ceramic plain surface or spherical surface. The steel bolt also available upon requests |

Packing:

Wooden Crate Ply-Wood Pallet