The rubber-ceramic lining of pulley is particularly suitable in cases where slippage and excessive wear make normal rubber lining ineffective. Alumina ceramics tiles allow to maintain the correct position of the belt, even in conditions of high humidity, heavy pollution and abrasive impact. Also, by varying the thickness of the ceramic elements and the total thickness of the lining, it is possible to compensate the difference in diameters of the pulleys

A. Rubber:

1. Material: NR&BR

2. Density: 1.15 g/sm

3. Tensile strength: 24 MPa

4. Shore hardness: 60±5

5. Elongation: 360%

6. Wear lost: 85 mm3

7. Ageing coefficient: 0.87 (70C°x48 hours)

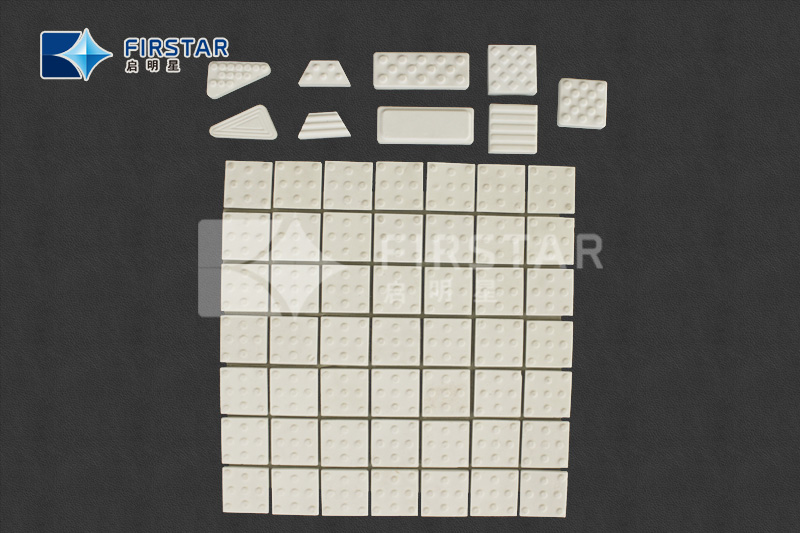

B. Alumina ceramics:

1. Material: Al2O3 92-95%

2. Density: 3.6 g/cm3

3. Colour: wight

4. Wear lost:<0.20cm3

5. Hardness: Mohs 9